Storage racks are shelf-like frameworks or stands found in plants and factories, workshops, retail facilities, homes, and offices alike. The applications of storage racks are virtually endless. They offer their users a means to efficiently store, organize, and/or display tools, equipment, materials, pallets, boxes, parts, and products. Read More…

Ridg-U-Rak produces more than 100 million pounds of pallet rack, high density storage rack and specialized rack systems annually. A customer-centric, full-service pallet rack producer with over 400,000 square feet of production and warehouse space, Ridg-U-Rak offers engineering, design, project management and installation services that meet your pallet rack needs on time and on budget.

Steel King offers the industry’s widest selection of rack types, including roll-form and structural pallet racks, drive-in racks, gravity flow and push back storage systems, multi-level pick modules, automation integration, cantilever racks, portable racks, and custom shipping racks. Plus a full-line of guard rail and rack protection products. Full engineering staff and more than 200 standard...

Donobrog is a leading material handling supplier. Since 1985, we have provided high-quality pallet racks and racking systems. We offer many other products, including mezzanine staircases, flow racks, guard railing and more. Expect excellent service on simple and difficult jobs.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

At East Coast Storage Equipment, we specialize in providing robust, reliable storage solutions through our extensive line of storage racks. With decades of experience, we supply, install, and service a wide variety of high-quality rack systems, tailored to meet the diverse storage needs of warehouses, distribution centers, and industrial facilities.

More Storage Rack Manufacturers

Storage racks offer essential space-saving solutions in shipping areas, product assembly rooms, workspaces, and manufacturing facilities. Whether you’re organizing a warehouse, retail store, or office, storage rack systems provide efficient inventory management, improved workflow, and optimized use of available space. Modern storage racks are integral to logistics, distribution, and supply chain operations, supporting a wide range of industries with flexible, scalable storage options.

Industries that utilize storage racks for inventory include home furnishings, garage and automotive services, food and beverage, education, material handling, postal services, healthcare, banking, military, government, office, industrial manufacturing, pharmaceuticals, retail, logistics, warehousing, and many more. From pallet racking systems in distribution centers to wire shelving in commercial kitchens and modular shelving in medical facilities, storage racks play a crucial role in keeping operations organized and efficient.

History

Storage racks are an evolution of the basic shelving unit, which has existed in various forms for a long time. The development of storage racks was driven by industrialization and the invention of the forklift. In the early 1900s, manufacturers needed to enhance storage as they produced more bulk items and products for large stores, facilitated by nationwide shipping capabilities. To accommodate this, larger storage systems were created, giving rise to the modern storage rack industry.

In 1917, the Clark Material Handling Company introduced the first forklift after years of development. The forklift enabled manufacturers to build taller and more expansive storage racks and move items more quickly and safely with fewer people, revolutionizing warehouse storage and material handling processes.

During World Wars I and II, the demand for storage racks increased with the need for vehicles, weapons, and goods for the war effort. This period also saw the development of the standardized pallet, which led to forklifts capable of lifting multiple pallets simultaneously. In response, engineers created the pallet rack, the first true storage rack, designed to hold pallets. In 1926, manufacturers installed the first vertical pallet storage racks in warehouses, allowing better space utilization by stacking products upright.

In 1968, American inventor Thomas J. Finlayson patented the drive-in pallet rack, enabling machinery operators to drive directly to the storage rack. Nearly twenty years later, in 1986, Charles “Chuck” Agnoff, another American inventor, designed the gravity flow storage method, which continues to help manufacturers use storage rack systems more effectively and efficiently.

Today, storage racks are more useful than ever, offering increased durability, security, and versatility. With the rise of e-commerce, omni-channel distribution, and high-density warehouse storage, advanced racking systems have become indispensable for modern business operations. Automation and integration with warehouse management systems (WMS) have further streamlined inventory control and retrieval.

Design

Storage rack manufacturers typically build their products using welding, ensuring that the materials are strong and securely joined. The welded parts are usually made from durable metals such as stainless steel, aluminum, or titanium. For customers needing less durability, manufacturers may use materials like particle board or wood. The choice of materials depends on customer specifications, including durability, temperature resistance, load capacity, and corrosion resistance.

Manufacturers offer storage racks in a variety of designs, which can be fabricated or assembled. Customers can start by selecting from stock dimensions and designs, presenting detailed custom requests, or collaborating with the supplier to develop a custom design that fits unique storage needs.

When collaborating on a custom design, manufacturers and customers discuss various application details, including specifications and requirements, available floor and ceiling capacity, adequate storage space, load-bearing capacity, seismic considerations, and mobility needs. After these discussions, the manufacturer sketches a system design and submits it for customer approval. Once approved, fabrication begins. For standard or custom orders, contact a reputable storage rack manufacturer today.

Do you need help choosing the right storage rack design? Ask yourself: What will you be storing? How much weight must each shelf support? Will you need flexibility for future expansion? Are there specific environmental conditions (such as temperature or humidity) that require specialized materials or coatings?

Features

Storage rack systems utilize either a “first in, first out” (FIFO) method or a “last in, first out” (LIFO) method to organize and manage inventory. Each method provides distinct guidelines for stocking and picking materials, and the choice can significantly influence warehouse efficiency and order fulfillment accuracy.

In the FIFO method, stocking is done from the rear while picking occurs at the front. This technique is commonly used for perishable food inventory to ensure that the oldest items are sold first, thereby reducing waste and ensuring product quality. Industries such as grocery, pharmaceuticals, and food processing rely on FIFO racking systems to comply with regulations and maintain inventory turnover.

Conversely, the LIFO method is unsuitable for perishable items. It is used for products that can remain on storage shelves for extended periods without deterioration. LIFO is typically employed with push-back racks and other storage systems that benefit from its space-saving features. Non-perishable goods, construction materials, and some industrial supplies are often managed using LIFO systems for operational efficiency.

High-density storage racks, selective racking, and automated storage and retrieval systems (AS/RS) often incorporate both FIFO and LIFO features, depending on the specific application. These features help maximize storage capacity, streamline picking processes, and improve inventory accuracy across various industries.

Types

Some of the most common storage rack designs include:

- Industrial storage racks

- Metal storage racks

- Wire storage racks

- Pallet racks

- Flow racks

- Push-back racks

- Rolling racks

- Cantilever racks

- Cryogenic racks

Each type of storage rack is engineered to address specific storage requirements and operational challenges. Understanding the differences between each rack system can help buyers select the ideal solution for their facility.

Industrial storage racks are heavy-duty racks made to hold heavy items and machinery, always constructed from durable metals like stainless steel or powder-coated steel for maximum strength and longevity. They are widely used in warehouses, factories, and distribution centers for storing equipment, automotive parts, and bulk materials.

Metal storage racks encompass any racks made of metal, typically steel or aluminum, and are used for heavy-duty warehouse storage applications. For organizations requiring lightweight or corrosion-resistant storage, options include racks made of particle board, wood, or titanium, which can be used in environments with specific requirements such as cleanrooms or wet areas.

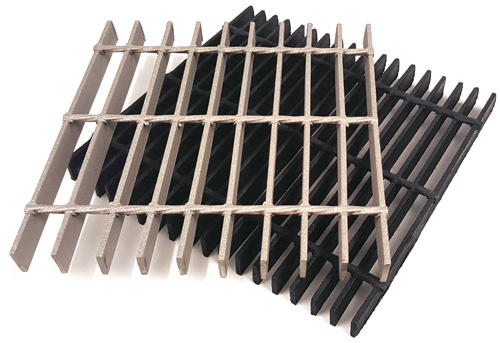

Wire racks consist of vertical metal rails with woven or welded wire mesh decks, sometimes featuring open shelves. Their grid patterns make them ideal for display applications, as they increase ventilation and decrease dust buildup. Wire shelving is often used in commercial kitchens, retail displays, labs, and healthcare settings where cleanliness and air circulation are important.

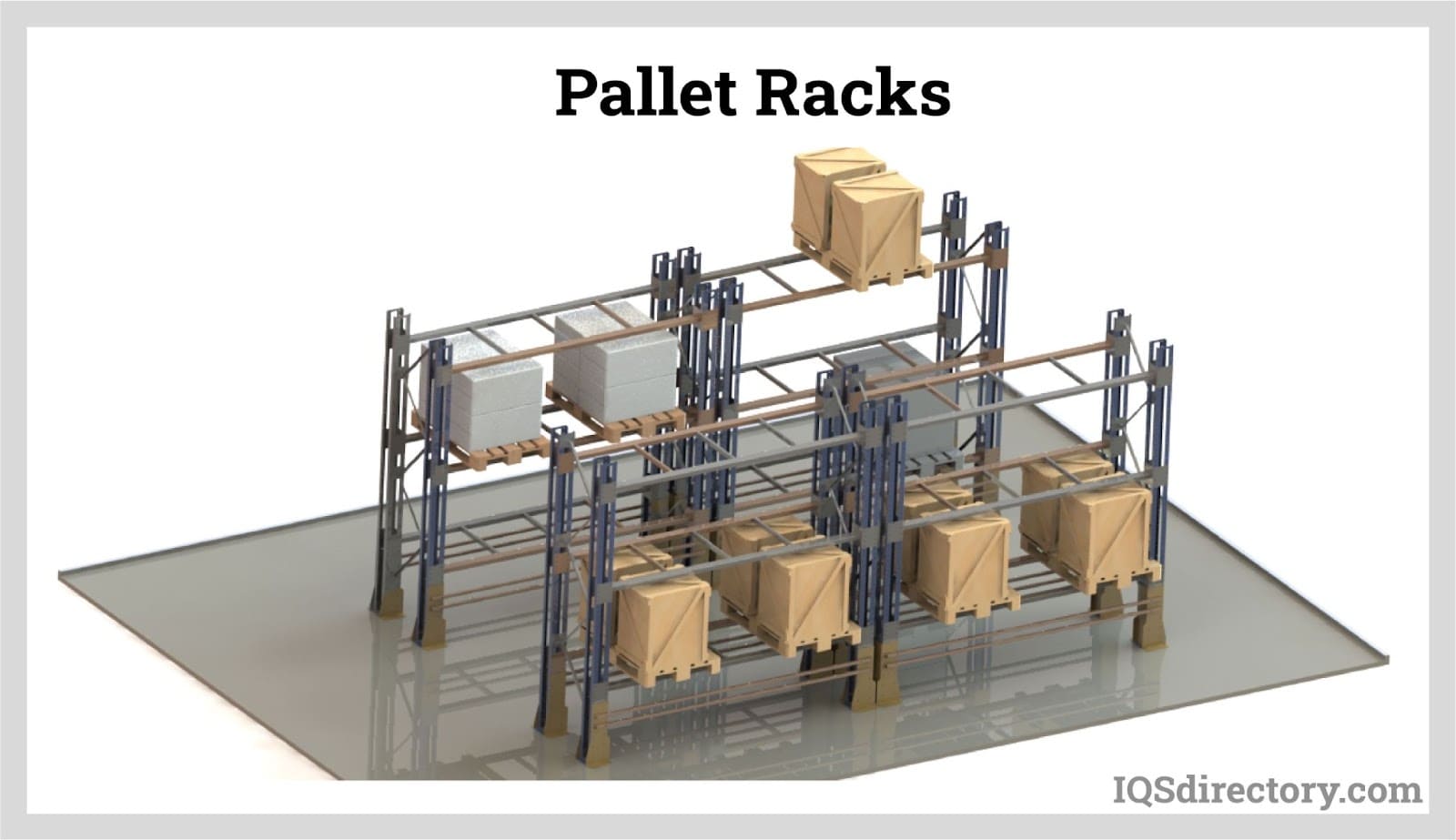

Pallet racks are designed to store inventory on pallets or skids. Open on all sides and allowing for vertical stacking, pallet racks have been popular since World War II and are used in warehouses, retail centers, manufacturing facilities, and distribution centers. Subtypes include drive-in racks, drive-through racks, pallet flow systems, push-back pallet rack systems, and compact mobilized pallet racks. These systems support both FIFO and LIFO inventory management, and can be tailored to maximize space in high-density storage environments.

Flow racks, or gravity flow racks, move pallets along the sloped plane of their decking when placed on their rollers. They, along with push-back racks, offer safe, dynamic, high-density storage for cartons and pallets, using inclined decking with rails and rollers to maximize capacity. Gravity flow racks are ideal for order picking, case picking, and staging areas in warehouses, distribution centers, and assembly lines.

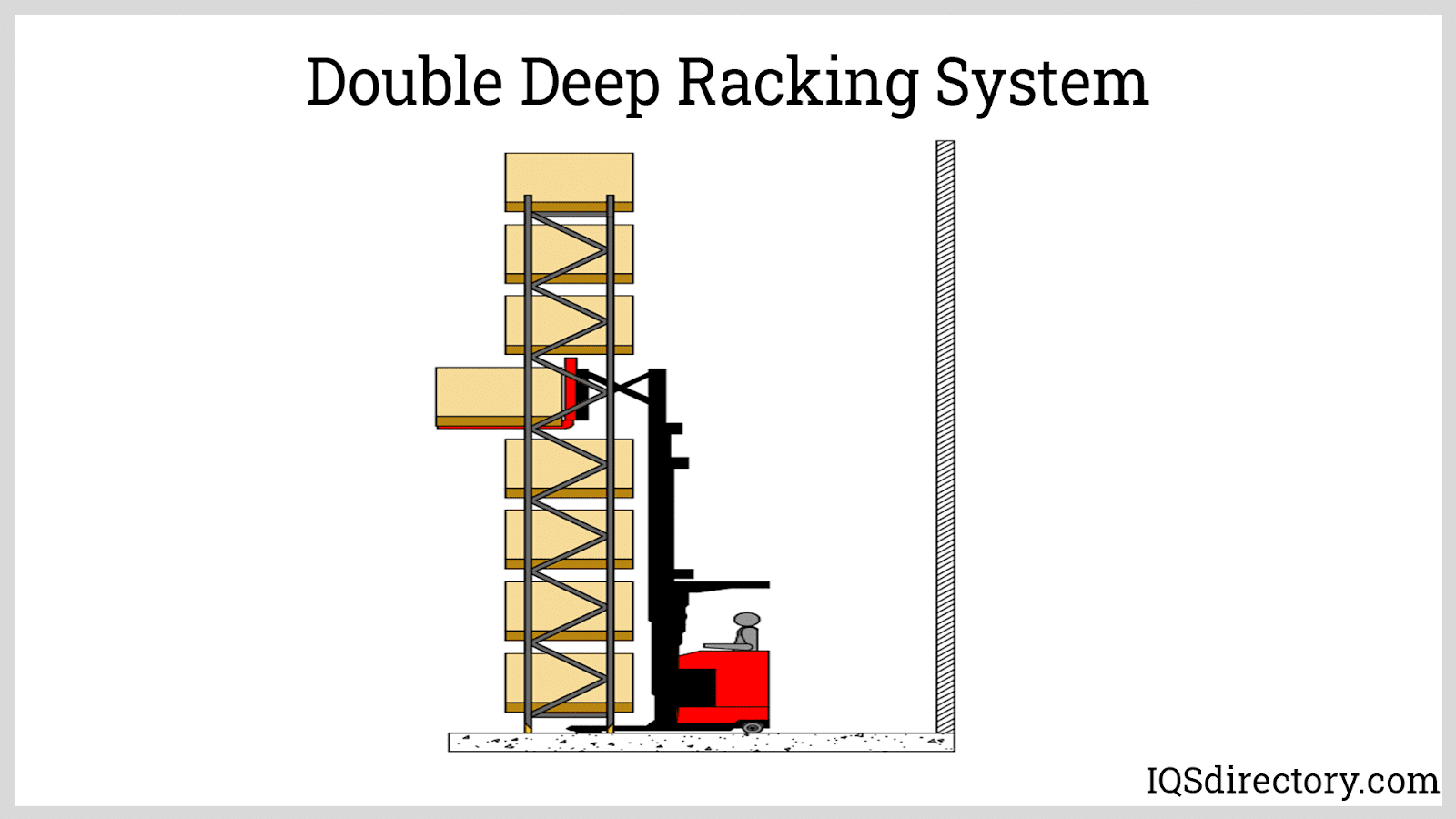

Push-back racks store each pallet on a wheeled cart placed on the system’s rails. Slightly angled down, when a forklift places pallets on them, the carts move toward the load/unload area, pushing the row of carts backward. Push-back racks save space by staying close together and are open on one side, making them easy to store against a wall. This design is popular in cold storage, food distribution, and any facility striving for high storage density and quick access.

Rolling racks can be static, used in picking and storing systems, or portable, like wire storage racks, and can be moved within a warehouse. Mobile storage racks are especially useful in environments where layout flexibility, seasonal inventory changes, or temporary storage is required, such as offices, retail backrooms, and event venues.

Cantilever racks consist of a vertical column, arms, a base, and cross/horizontal brace sets. Modular in design, they can accommodate new or changing storage requirements by allowing additional elements to be added. Used in plumbing supply warehouses, lumber yards, and woodworking shops, cantilever racks are designed to hold long, heavy items that must be kept off the ground, such as sheet metal, beams, boards, and rails. Cantilever racking solutions are perfect for managing building supplies, steel pipes, and other oversized products.

Cryogenic storage racks are used for storing materials at extremely low temperatures. Cryogenics, a branch of physics, deals with materials at temperatures below -292℉, as designated by the U.S. National Institute of Standards and Technology. Cryogenic racks are critical for laboratories, biotechnology firms, and medical facilities handling temperature-sensitive samples or pharmaceuticals.

In the home, storage racks are used not only to organize garages or basements but also for specialty tasks. Specialty storage racks include:

- Amp racks – used to mount amplifiers and other professional audio equipment for musicians, sound engineers, and event venues.

- Bicycle racks – store bikes when not in use, suitable for residential garages, public spaces, and commercial bike storage facilities.

- Eco racks – a type of bike rack designed to allow bike riders to haul a similar amount of weight as they could with a car, making commuting with bikes both eco-friendly and economical.

- Drying racks – used to hang wet clothes for drying, ideal for laundry rooms, apartments, and environmentally conscious households.

Looking for a specialized storage rack for your unique needs? Explore: What items do you need to store? Do you require a rack with security features, mobility, or specific load-bearing capacity? Will your storage rack be exposed to moisture, chemicals, or temperature fluctuations?

Accessories

There are various accessories available for storage racks that can enhance their functionality and adaptability for different storage requirements. Popular options include:

- Casters or wheels – add mobility to racks, making them easy to move or reposition for cleaning, inventory rotation, or reconfiguring warehouse layouts.

- Braces – provide extra stability and strength, especially when storing heavy or bulky items. Cross bracing is essential for seismic safety and tall installations.

- Anchors – secure the rack to the floor or wall, preventing tipping or accidental displacement, which is crucial for safety and code compliance.

- Bumpers – protective elements attached to the rack to prevent damage from collisions with forklifts, pallets, or carts.

- Drawer rack add-ons – convert open shelving into drawers, offering enclosed storage for smaller items, tools, or sensitive components.

- Shelf units – additional shelves that can expand the storage capacity vertically, allowing for multi-level organization.

- Baskets – provide a convenient solution for storing loose or irregularly shaped items, keeping them organized and easily accessible.

- Feet – elevate the rack off the ground, protecting the contents from moisture and facilitating cleaning underneath, ideal for food storage and healthcare environments.

- Dividers – create separate compartments within a shelf or drawer, enabling better organization for parts, tools, or inventory.

- Arms or hangers – attach to the sides of the rack to hang tools, clothing, hoses, or other items, maximizing available storage space.

To determine which storage rack accessories are needed for a specific application, consider several factors. First, assess the intended use of the rack and the type of items to be stored. For example, if mobility is required, casters or wheels would be beneficial. If the rack is tall or will hold heavy items, braces and anchors may be necessary to ensure stability and safety. Additionally, consider the available space and layout to determine if additional shelves, baskets, or dividers are needed for optimal organization. Assess any specific requirements, such as protecting delicate items with bumpers or utilizing hanging storage with arms. By evaluating the specific needs of the application, you can select the appropriate accessories to enhance the functionality and efficiency of your storage rack.

Are you seeking ways to improve your storage rack system’s efficiency? Consider: Which accessories will maximize your available space, increase safety, and streamline your workflow?

Applications

Storage racks are utilized in a diverse array of environments, each with distinct requirements and operational priorities. Key applications include:

- Warehousing and Distribution Centers – Pallet racking systems, selective racks, and high-density storage racks streamline order fulfillment, enable better inventory management, and facilitate safe, efficient product storage.

- Retail and E-Commerce – Stockrooms, showrooms, and fulfillment centers use shelving and display racks to organize merchandise, optimize pick-and-pack workflows, and enhance customer experience.

- Manufacturing Facilities – Storage racks support just-in-time (JIT) inventory management, parts storage, and work-in-process staging, helping manufacturers reduce downtime and maintain production flow.

- Automotive and Aerospace – Specialized racking systems store parts, tires, tools, and raw materials, supporting assembly lines and maintenance operations.

- Food and Beverage – Food-grade wire shelving, refrigerated racking, and FIFO systems maintain compliance with safety regulations and ensure optimal stock rotation.

- Pharmaceutical and Healthcare – Medical shelving, cleanroom racks, and cryogenic storage systems facilitate safe, organized storage of medications, equipment, and temperature-sensitive specimens.

- Education and Libraries – Mobile shelving, book racks, and archival storage solutions improve space utilization and accessibility in schools, universities, and public libraries.

- Government and Military – Secure, heavy-duty storage racks house mission-critical supplies, records, and equipment, meeting stringent regulatory and safety standards.

- Offices – Document shelving, file storage, and modular racking systems keep workspaces organized and support efficient business operations.

- Residential and Commercial Storage – Garage racking, basement shelving, and specialty storage racks help homeowners and businesses maintain clutter-free, organized environments.

Curious about the best storage solution for your industry? Search: What storage rack types are most effective for my business sector? How can I improve efficiency and safety in my storage areas?

Benefits

Investing in the right storage rack system provides significant benefits for both commercial and industrial operations. Key advantages include:

- Space Optimization – Maximize use of available floor and vertical space, reducing the footprint required for storage and freeing up valuable real estate for other activities.

- Increased Efficiency – Streamlined storage and retrieval processes reduce labor costs and improve workflow, supporting rapid order picking and inventory turnover.

- Enhanced Safety – Engineered racking systems with safety accessories protect workers, inventory, and equipment from accidents and damage.

- Flexibility – Modular and adjustable racks adapt to changing storage requirements, seasonal inventory fluctuations, and evolving business needs.

- Inventory Control – Improved organization and labeling options enable more accurate tracking, reduced shrinkage, and better compliance with industry regulations.

- Cost Savings – Efficient storage reduces the need for additional warehouse space, lowers energy costs, and minimizes product loss or damage.

- Improved Accessibility – Well-designed racks make it easier for staff to access products, tools, or supplies, boosting productivity and morale.

Want to learn more about the cost-saving potential of storage rack systems? Ask: How can a new racking solution reduce my operational expenses? What ROI can I expect from upgrading my warehouse storage system?

Standards

Since storage racks are commonly used in workplaces in the United States, they must always comply with OSHA safety requirements to protect employees and assets. Other storage rack standards depend on the application and location. For example, storage racks in public areas prone to seismic activity, such as public libraries or California warehouses, must adhere to FEMA design and installation standards for earthquake resistance. Storage racks used in the medical or food and beverage industries must meet FDA standards, ensuring hygienic, contaminant-free storage. This applies to other settings as well, such as military bases (Mil-Specs), offices, and accessible areas (ADA-compliant). Frequently, standard guidelines are issued by organizations like ANSI (American National Standards Institute), ISO (International Organization for Standardization), and NFPA (National Fire Protection Association).

Are you compliant with all required safety and industry standards? Review: What codes or certifications must my storage racks meet? How can I ensure ongoing compliance and safety in my facility?

Things to Consider

To find the ideal storage rack manufacturer for your needs, start by reviewing the companies listed on this page. Each company we feature is reputable and a proven leader in the industry, offering a wide selection of industrial shelving, commercial racks, and custom storage solutions.

To streamline your search, create a list of your own specifications, including your budget, timeline, delivery preferences, and post-delivery support needs (such as installation, maintenance, and warranties). Assess your space constraints, load capacity requirements, and any environmental or regulatory considerations specific to your facility.

With your list ready, explore the profiles of the listed companies. Compare their services and product offerings, and select three or four that seem to best match your needs. Reach out to these candidates, using your specifications as a guide, and discuss your project in detail. Ask about lead times, customization options, installation support, and after-sales service. Finally, choose the manufacturer that not only offers the best value but also provides a storage solution that aligns closely with your requirements. Good luck!

Ready to take the next step? Consider: What is the total cost of ownership for each storage rack system? How will your choice impact workflow, safety, and future scalability?

Frequently Asked Questions (FAQ)

- What is the difference between pallet racking and shelving?

Pallet racking is designed for storing palletized goods and is typically accessed with forklifts, while shelving is for lighter, hand-loaded items. Selecting between the two depends on your inventory type, storage density, and access needs. - Can I customize my storage rack system?

Yes, most manufacturers offer modular and fully custom storage solutions tailored to fit your space, weight requirements, and operational workflow. Options include adjustable shelving heights, specialized coatings, locking mechanisms, and integrated safety features. - How do I determine the right load capacity for my racks?

Calculate the heaviest items you plan to store and add a safety factor. Consult with manufacturers for engineering guidance, especially for seismic zones or high-density storage applications. - How often should storage racks be inspected?

Regular inspections are recommended—at least annually, or after any major impacts or seismic events. Inspections ensure safety, compliance, and the prevention of costly accidents or inventory loss. - Do I need professional installation?

For large-scale or high-density racking systems, professional installation ensures safety, compliance, and optimal performance. Some smaller or modular racks can be assembled in-house following manufacturer instructions.

Still have questions about storage racks? Contact a storage rack specialist or manufacturer for personalized advice and site assessments.

Get Started: Choosing the Best Storage Rack Solution

Whether you are setting up a new warehouse, upgrading your existing facility, or simply trying to organize your space more efficiently, selecting the right storage rack system is a critical decision. Start by clearly defining your storage needs, space constraints, and operational goals. Research leading storage rack manufacturers, compare product lines and services, and don’t hesitate to ask for references or case studies.

Ready to increase your facility’s efficiency and safety with a modern storage rack system? Take action:

- Request a quote from top storage rack suppliers.

- Schedule a site evaluation to assess your storage challenges and opportunities.

- Ask about turnkey solutions, including design, delivery, installation, and ongoing maintenance.

- Compare warranty and service agreements to ensure long-term satisfaction and safety.

By investing in the right storage rack system, you’ll optimize your organization’s space, streamline operations, and create a safer, more productive environment for your team.

For more information—and to find the ideal storage rack manufacturer for your project—explore our comprehensive manufacturer listings now.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services