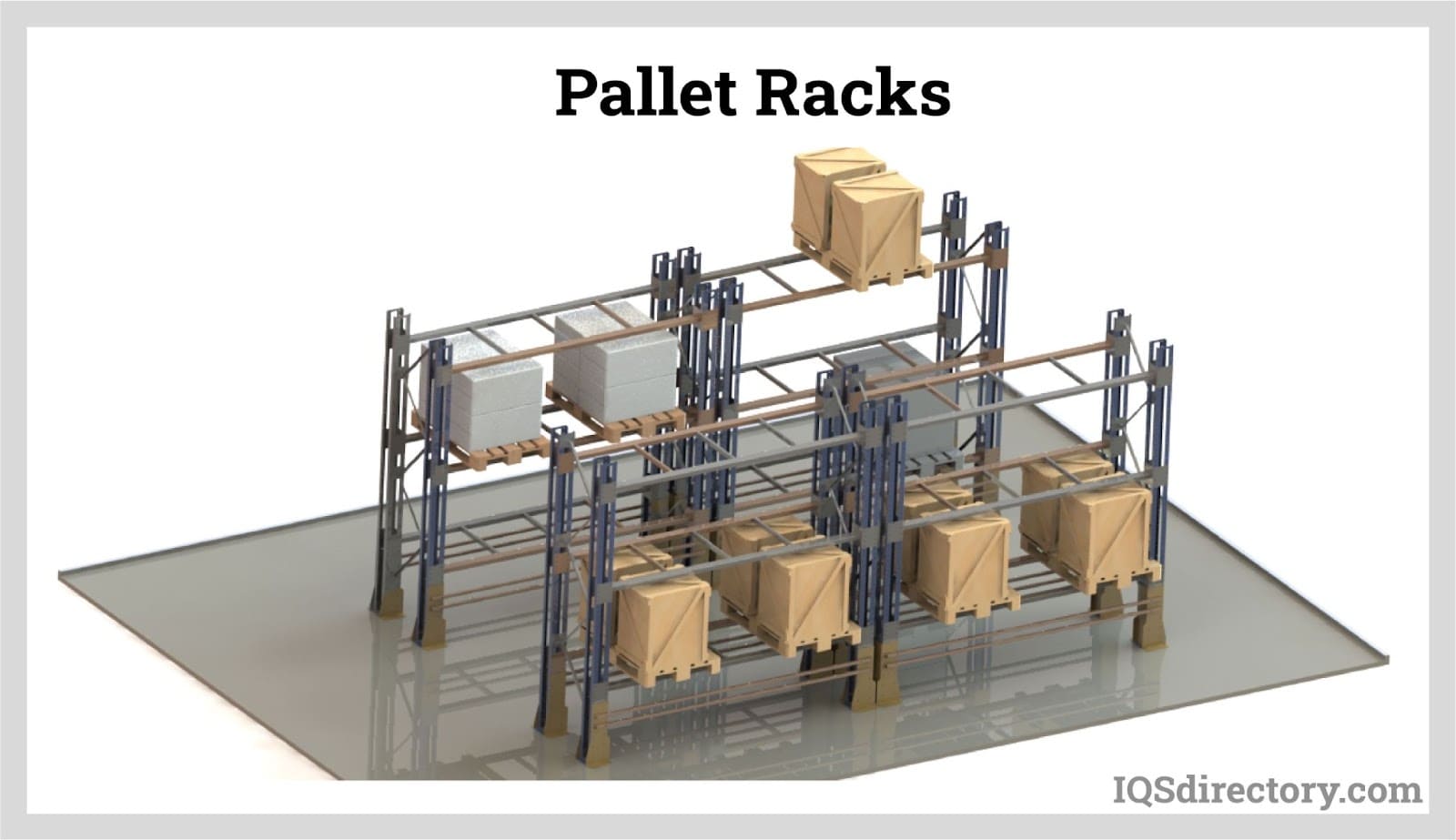

A pallet rack is a steel structure that is upright and consists of connectors and beams that are clipped, welded, or bolted together to create a shelving unit for storing equipment and inventory. Pallet racks are considered to be the essential component for providing a sturdy method in warehousing for locating and organizing stored materials. Read More…

Ridg-U-Rak produces more than 100 million pounds of pallet rack, high density storage rack and specialized rack systems annually. A customer-centric, full-service pallet rack producer with over 400,000 square feet of production and warehouse space, Ridg-U-Rak offers engineering, design, project management and installation services that meet your pallet rack needs on time and on budget.

Steel King offers the industry’s widest selection of rack types, including roll-form and structural pallet racks, drive-in racks, gravity flow and push back storage systems, multi-level pick modules, automation integration, cantilever racks, portable racks, and custom shipping racks. Plus a full-line of guard rail and rack protection products. Full engineering staff and more than 200 standard...

Quality Material Handling (QMH) is a leading total solutions provider for boltless shelving, warehouse racking, storage systems, mezzanines, and dock equipment. With over 29 years of experience and an in-house fabrication facility, QMH designs and manufactures innovative custom solutions such as dock platforms and ramps that solve difficult loading and unloading challenges. We are a full-service...

Donobrog is a leading material handling supplier. Since 1985, we have provided high-quality pallet racks and racking systems. We offer many other products, including mezzanine staircases, flow racks, guard railing and more. Expect excellent service on simple and difficult jobs.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

United Material Handling, Inc. is committed to delivering top-tier storage rack solutions that help our clients maximize space, improve efficiency, and enhance their overall operational capabilities. Specializing in a diverse range of storage systems, we offer pallet racks, cantilever racks, flow racks, and custom storage racking solutions tailored to meet the unique needs of businesses across...

At East Coast Storage Equipment, we specialize in providing robust, reliable storage solutions through our extensive line of storage racks. With decades of experience, we supply, install, and service a wide variety of high-quality rack systems, tailored to meet the diverse storage needs of warehouses, distribution centers, and industrial facilities.

More Pallet Rack Manufacturers

Pallet racks are engineered storage solutions designed to optimize warehouse space, increase operational efficiency, and safely store virtually any product type, from industrial tools and heavy machinery to retail clothing and temperature-sensitive food. As a cornerstone of modern warehouse racking systems, pallet racks provide the durability, versatility, and scalability required for efficient inventory management across a broad range of industries.

Understanding How Pallet Racks Are Made

High-quality pallet racks are composed of key structural components that ensure strength, adaptability, and safety in warehouse storage environments. Here’s an in-depth look at the primary elements of industrial pallet racking systems:

Upright Frame - The upright frame consists of vertical steel columns that are anchored to the warehouse floor. These columns typically feature a series of evenly spaced holes, allowing for adjustable placement of cross beams and shelf levels. The frame height and depth are calculated based on the size of the pallets to be stored, load requirements, and ceiling clearance, which together determine the optimal racking configuration and number of storage levels. Choosing the correct upright frame dimensions is essential for warehouse optimization, maximizing vertical storage, and ensuring compliance with building codes and safety standards.

Cross Beams – Cross beams, also known as horizontal load beams, play a critical role in warehouse pallet racking systems. These beams connect to the upright frames via brackets and locking mechanisms, forming the shelf platforms that support pallet loads. The beam length, profile, and load capacity are tailored to the type of stored inventory, whether standard pallets, oversized goods, or mixed SKU storage. Proper installation and regular inspection of cross beams are vital for preventing rack collapse and ensuring operational safety in distribution centers and logistics facilities.

Anchor Bolts – Anchor bolts are heavy-duty fasteners that secure the feet of upright frames to the concrete warehouse floor. Correct installation of anchor bolts is essential for seismic compliance, warehouse safety, and rack stability, especially in high-traffic or earthquake-prone areas. Using industry-approved anchor bolt patterns and base plate sizes helps distribute the load evenly and prevents accidental rack displacement or tip-over incidents.

Base Plate – The base plate is a reinforced steel plate welded or bolted to the bottom of each frame column. Its primary function is to anchor the racking system and distribute weight across the floor slab, reducing point loads and protecting both the racking structure and the facility’s foundation. Properly sized base plates are a key factor in meeting OSHA and local safety requirements for industrial shelving and warehouse rack systems.

Cross Bars – Cross bars, also known as pallet supports, run perpendicular to the cross beams and provide added safety by supporting pallets and helping distribute loads evenly. Available in both diagonal and horizontal designs, cross bars enhance rack stability and prevent pallet drop-through, a common safety hazard in busy warehouses. They are especially important in selective racking and heavy-duty shelving applications.

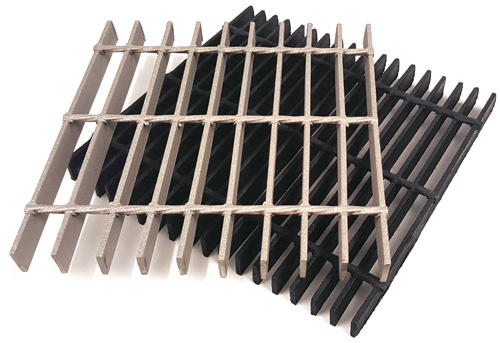

Rack Decking – Rack decking refers to the surface placed over cross beams to provide a stable platform for pallets and non-palletized items. Popular decking materials include wire mesh, steel panels, and wood, each selected based on fire safety codes, load requirements, and the nature of the inventory. Wire decking improves visibility, promotes airflow, and helps meet NFPA fire code requirements, making it a preferred choice for many warehouse racking installations.

Types of Pallet Rack Systems

There are several types of pallet racking systems, each engineered to address specific storage, access, and space utilization needs. Understanding the best pallet rack type for your facility is crucial for optimizing workflow, protecting inventory, and lowering operational costs. Explore the most common pallet racking options below:

Cantilever Pallet Racks

Cantilever racks are designed for storing long, bulky, or irregularly shaped items that cannot be accommodated by traditional pallet racks. Typical applications include lumber, steel pipes, furniture, and building materials. With robust upright columns and adjustable horizontal arms, cantilever racking offers a flexible, open-front design that facilitates easy loading and retrieval by forklifts or side loaders. The system's weight capacity is determined by arm length, steel gauge, and column spacing, supporting everything from light-duty retail goods to heavy industrial materials.

Selective Pallet Racking

Selective pallet racking is the most prevalent warehouse racking system, known for its direct access to every pallet and flexible shelf configurations. This system enables efficient stock rotation (FIFO), rapid order picking, and straightforward inventory control. Each pallet position is directly accessible, minimizing labor costs and reducing handling times. Selective racks are ideal for high SKU counts, frequent stock turnover, and warehouses prioritizing accessibility and visibility.

Wondering how to optimize your warehouse for both space and accessibility? Selective pallet racking could be the answer. These racks simplify inventory counts, support just-in-time inventory management, and are easily reconfigured as your storage needs evolve.

Push-Back Pallet Racking

Push-back racking systems are engineered for high-density storage where space optimization is critical. Pallets are loaded onto nested carts or shelf trays that glide along inclined rails within the rack frame. When a new pallet is loaded, it pushes the previous pallet back, enabling Last-In, First-Out (LIFO) inventory management. Push-back racks reduce aisle space requirements, increase storage density, and are suitable for warehouses with limited floor space or fast-moving inventory with moderate SKU variety.

Drive-In and Drive-Through Pallet Racks

Drive-in and drive-through pallet racks are designed for maximum storage density and are commonly used in cold storage, food distribution, and high-volume inventory environments. These systems allow forklifts to enter the rack structure for pallet placement and retrieval, eliminating the need for multiple aisles. Drive-in racking uses a single entry/exit point (LIFO), while drive-through racking provides access from both ends (FIFO). These racks are best suited for low SKU counts and large quantities of homogeneous products.

Other Pallet Rack Systems

Additional racking options include:

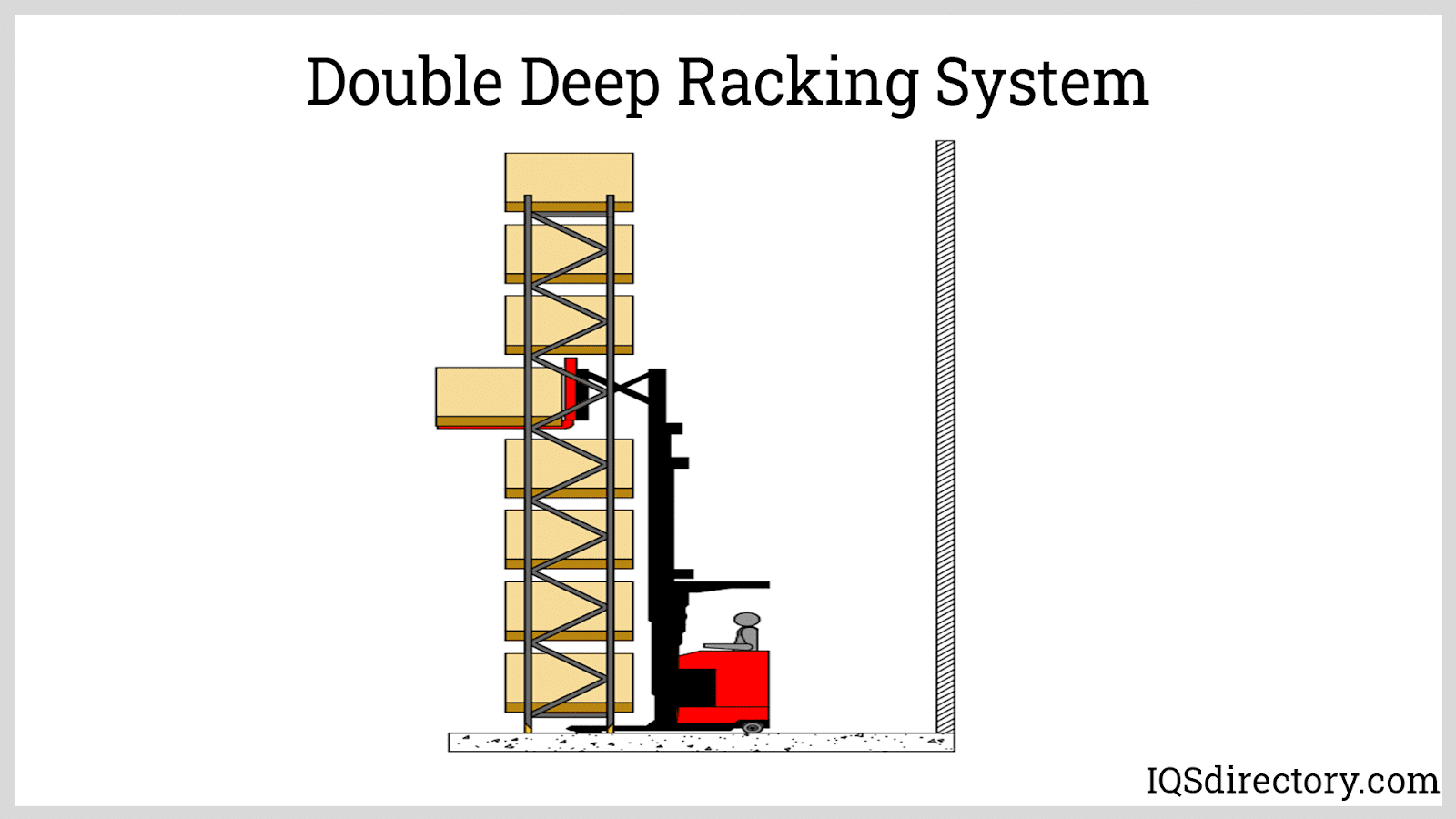

- Double-Deep Pallet Racking – Pairs two rows of selective racks back-to-back, doubling storage capacity while maintaining reasonable selectivity. Ideal for warehouses with limited space and high throughput requirements.

- Pallet Flow Racking – Also known as gravity flow racks, these systems use rollers or conveyor lanes to move pallets from the loading side to the picking side, ensuring FIFO inventory rotation and efficient order fulfillment.

- Carton Flow Racking – Optimized for smaller boxes or cartons, these racks use inclined shelves and rollers to move inventory toward pick faces, streamlining order picking in distribution centers.

- Mobile Pallet Racking – Mounted on motorized bases, these racks can be moved to create access aisles as needed, maximizing storage density and flexibility in high-value warehouse environments.

Key Benefits of Pallet Racking Systems

Investing in the right pallet racking system delivers a range of advantages that directly impact warehouse performance, employee safety, and inventory management. Here’s why leading industrial companies, retailers, and logistics providers rely on pallet rack solutions:

- Space Optimization – By utilizing vertical space and minimizing aisle width, warehouse pallet racks dramatically increase usable storage capacity and free up valuable floor space for other operations.

- Bulk Storage Capacity – Modern racking systems are engineered to store heavy, oversized, or high-volume inventory, supporting efficient material handling and streamlined workflows.

- Improved Inventory Control – Clearly defined storage locations and easy access to every pallet simplify inventory tracking, reduce picking errors, and support robust warehouse management systems (WMS).

- Customization and Flexibility – Pallet racks are available in a wide range of sizes, load capacities, and configurations, allowing you to tailor your racking system to your unique storage requirements, including seismic-rated and food-grade options.

- Enhanced Safety – Properly installed and maintained racking systems protect workers and inventory from accidents, while accessories like safety bars, wire decking, and rack guards further mitigate risks in busy facilities.

- Cost-Efficiency – Optimized racking layouts reduce storage costs per pallet, improve picking productivity, and lower total cost of ownership through durable, long-lasting construction.

- Scalability – Modular designs allow for future expansion as your business grows, accommodating changing inventory profiles and new workflow requirements.

- Compliance – Well-designed pallet rack systems are built to meet local building codes, fire safety standards, and industry regulations, minimizing liability and supporting insurance requirements.

Common Applications and Industries for Pallet Racks

Pallet racks are indispensable in a wide array of industries and storage environments. Some of the most common applications include:

- Warehousing and Distribution Centers – Maximize throughput, improve inventory accuracy, and support rapid order fulfillment for e-commerce, retail, and wholesale operations.

- Manufacturing Facilities – Store raw materials, work-in-process components, and finished goods efficiently, supporting lean manufacturing and just-in-time production.

- Cold Storage and Food Distribution – Drive-in and selective racks are ideal for temperature-controlled environments, ensuring compliance with food safety standards and efficient inventory rotation.

- Automotive and Industrial Parts Storage – Accommodate heavy or irregularly shaped items using cantilever or custom racking systems for safe and organized storage.

- Retail Stockrooms and Big Box Stores – Utilize pallet racks to streamline backroom storage, support fast-moving consumer goods, and maintain high inventory turnover rates.

- Archival and Document Storage – Securely store records, archives, and sensitive materials using high-density racking and secure shelving solutions.

Factors to Consider When Selecting Pallet Racks

Choosing the right pallet racking system for your warehouse or storage facility involves careful consideration of several key factors. Use the following checklist when researching pallet rack suppliers or planning your storage upgrade:

- Load Requirements – Assess the maximum weight per pallet, shelf, and bay. Consider both static and dynamic loads for safe operation.

- Pallet Dimensions – Determine the standard pallet size (e.g., 48"x40") and any specialty pallets or odd-shaped items you need to accommodate.

- Warehouse Layout – Map out available floor space, ceiling height, column locations, and forklift access paths to optimize racking placement.

- Inventory Turnover and SKU Variety – High-turnover, high-SKU environments benefit from selective or carton flow racks, while bulk storage favors push-back or drive-in racks.

- Material Handling Equipment – Ensure compatibility with your forklifts, pallet jacks, and automated storage/retrieval systems (AS/RS).

- Safety and Compliance – Check for seismic ratings, fire safety certifications, and OSHA compliance to protect workers and inventory.

- Budget and ROI – Balance initial investment against long-term cost savings, maintenance needs, and potential for future expansion.

- Installation and Maintenance – Evaluate supplier installation services, maintenance programs, and availability of replacement parts or upgrades.

Frequently Asked Questions About Pallet Racks

Looking for answers before making a purchase decision? Here are some of the most common questions buyers ask when researching warehouse racking solutions:

- What is the typical lifespan of a pallet rack system? With proper installation and regular maintenance, industrial pallet racks can last 15-20 years or longer, depending on usage and environmental conditions.

- How do I determine the right rack configuration for my warehouse? Consult with an experienced pallet rack supplier or warehouse design specialist to analyze your space, inventory, and material handling needs. Many suppliers offer CAD layouts and site assessments.

- Are used pallet racks a good option? Used pallet racks can offer cost savings, but always verify structural integrity, compatibility with your system, and compliance with current codes before purchase.

- What safety accessories should I consider? Popular accessories include column protectors, rack guards, wire decking, safety bars, and anti-collapse mesh for enhanced worker and inventory protection.

- Can pallet racks be relocated or reconfigured? Yes, modular racking systems are designed for easy reconfiguration and relocation as your storage needs change.

Choosing the Best Pallet Rack Supplier

To ensure a productive outcome when purchasing pallet racks from a trusted supplier, it’s essential to compare multiple companies and evaluate their expertise, capabilities, and customer support. Our comprehensive directory of pallet rack suppliers streamlines your search by providing:

- Detailed business profiles – Learn about each supplier’s specialties, product lines, and industry experience.

- Direct contact forms – Request quotes, ask technical questions, or schedule site assessments with ease.

- Website previews – Quickly review supplier offerings and resources before making a decision.

- RFQ tools – Send a single message to multiple suppliers, saving time and simplifying your purchasing process.

Ready to find the right pallet rack solution for your warehouse or facility? Browse our curated list of pallet rack suppliers, or contact us for expert guidance on warehouse layout design, installation services, or custom racking solutions tailored to your business needs.

Next Steps: How to Buy Pallet Racks

Begin your purchasing journey by:

- Assessing your current and future storage needs, including load types, volume, and workflow requirements.

- Researching different pallet racking systems and comparing their advantages for your specific application.

- Requesting site visits or layout consultations from experienced suppliers for tailored recommendations.

- Reviewing quotes and evaluating supplier credentials, installation options, and after-sales support.

- Placing your order and scheduling professional installation for maximum safety and performance.

Need help choosing or installing your pallet racking system? Contact our experts for personalized advice and solutions that fit your budget and operational requirements.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services