Roller racks are very common in the manufacturing and industrial world. Roller racks are known as flow or push-back types of pallet racks. Where pallet racks are the simplest way to store and house pallets when not in immediate use, roller racks are utilized in increasing storage capacity as they allow for the racks to move with ease along the pallet rack by the use of rollers. Read More…

Ridg-U-Rak produces more than 100 million pounds of pallet rack, high density storage rack and specialized rack systems annually. A customer-centric, full-service pallet rack producer with over 400,000 square feet of production and warehouse space, Ridg-U-Rak offers engineering, design, project management and installation services that meet your pallet rack needs on time and on budget.

Steel King offers the industry’s widest selection of rack types, including roll-form and structural pallet racks, drive-in racks, gravity flow and push back storage systems, multi-level pick modules, automation integration, cantilever racks, portable racks, and custom shipping racks. Plus a full-line of guard rail and rack protection products. Full engineering staff and more than 200 standard...

Quality Material Handling (QMH) is a leading total solutions provider for boltless shelving, warehouse racking, storage systems, mezzanines, and dock equipment. With over 29 years of experience and an in-house fabrication facility, QMH designs and manufactures innovative custom solutions such as dock platforms and ramps that solve difficult loading and unloading challenges. We are a full-service...

Donobrog is a leading material handling supplier. Since 1985, we have provided high-quality pallet racks and racking systems. We offer many other products, including mezzanine staircases, flow racks, guard railing and more. Expect excellent service on simple and difficult jobs.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

United Material Handling, Inc. is committed to delivering top-tier storage rack solutions that help our clients maximize space, improve efficiency, and enhance their overall operational capabilities. Specializing in a diverse range of storage systems, we offer pallet racks, cantilever racks, flow racks, and custom storage racking solutions tailored to meet the unique needs of businesses across...

At East Coast Storage Equipment, we specialize in providing robust, reliable storage solutions through our extensive line of storage racks. With decades of experience, we supply, install, and service a wide variety of high-quality rack systems, tailored to meet the diverse storage needs of warehouses, distribution centers, and industrial facilities.

More Roller Rack Manufacturers

Roller Racks: The Ultimate Guide to High-Density Storage Solutions

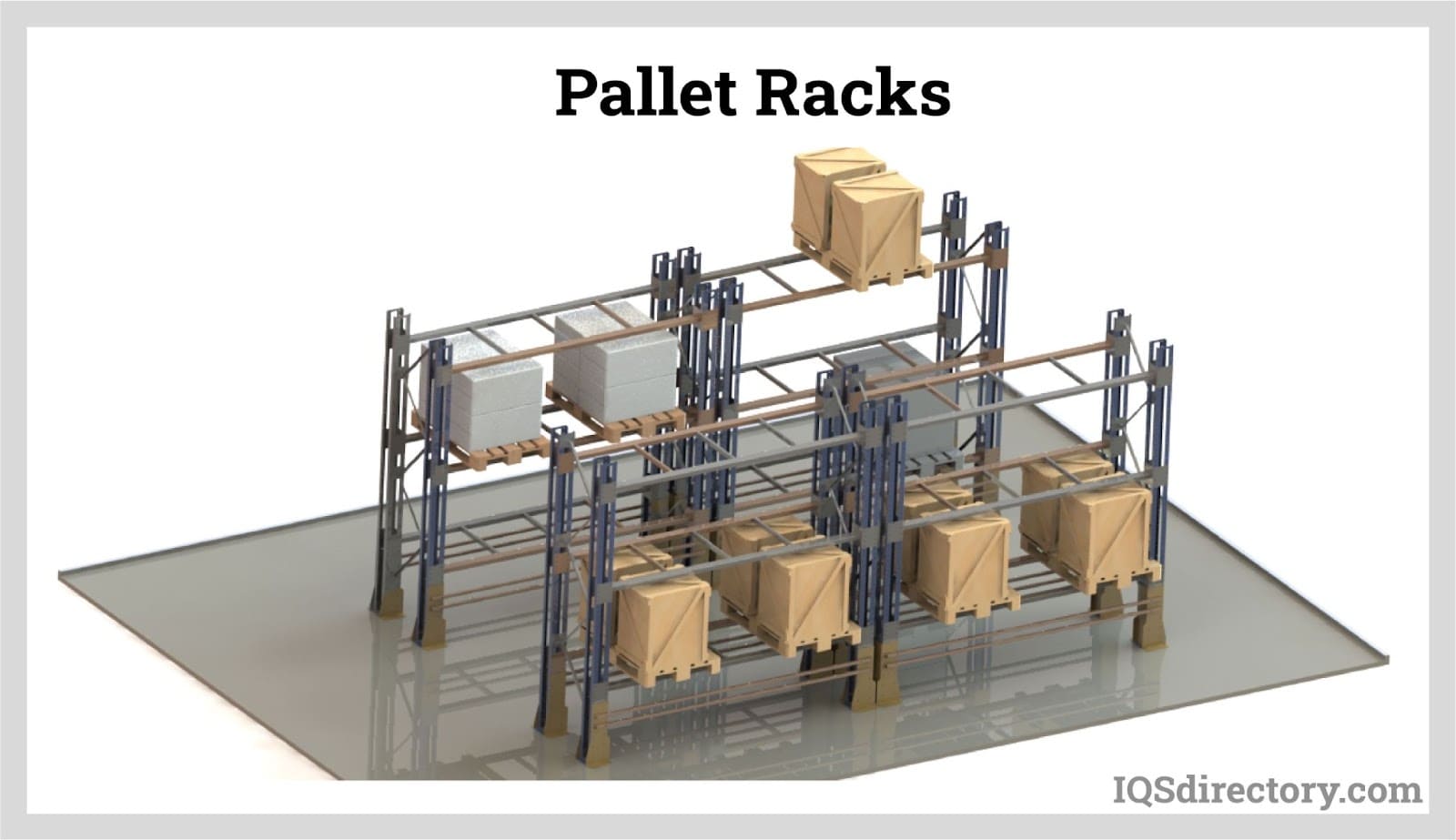

Roller racks, also known as flow racks or gravity flow racking systems, represent a cutting-edge solution for warehouses and distribution centers seeking to maximize storage density and operational efficiency. Unlike conventional pallet racking that depends on forklifts or other equipment for moving inventory, roller racks utilize rollers and gravity to allow racks or pallets to glide effortlessly into position. This design significantly reduces manual handling and the need for heavy machinery, making roller racks an ideal storage solution for environments with frequent inventory movement.

Whether you’re searching for industrial roller racks, pallet flow racking, or carton flow systems, understanding the key features, benefits, and applications of roller racks can help you select the best storage system for your facility. In this comprehensive guide, we’ll explore the mechanics of roller racks, types available, installation practices, real-world applications, and essential factors for evaluating roller rack manufacturers.

Why Choose Roller Racks for Your Storage Needs?

Are you evaluating storage rack systems for your warehouse, logistics center, or manufacturing plant? Roller racks offer unique advantages over traditional static shelving or selective pallet racking systems. Their innovative design not only enhances storage density but also boosts productivity and safety in high-traffic environments. If you are asking questions like, “How can I maximize warehouse space?” or “What is the most efficient inventory flow solution?”—roller racks may be the answer.

- Increased Storage Density: Roller racks optimize vertical and horizontal space, accommodating more SKUs or pallets per square foot than standard racking solutions.

- Improved Inventory Rotation: The gravity flow design supports first-in, first-out (FIFO) inventory management, essential for perishable goods and time-sensitive products.

- Reduced Labor Costs: With gravity doing the work, employees spend less time and effort retrieving or replenishing stock, increasing overall throughput.

- Enhanced Safety: By minimizing the need for forklifts in picking aisles, roller racks reduce the risk of workplace accidents and product damage.

- Versatile Applications: Roller racks are suitable for a wide range of industries, from food and beverage to automotive, pharmaceuticals, cold storage, and e-commerce fulfillment centers.

How Do Roller Racks Work?

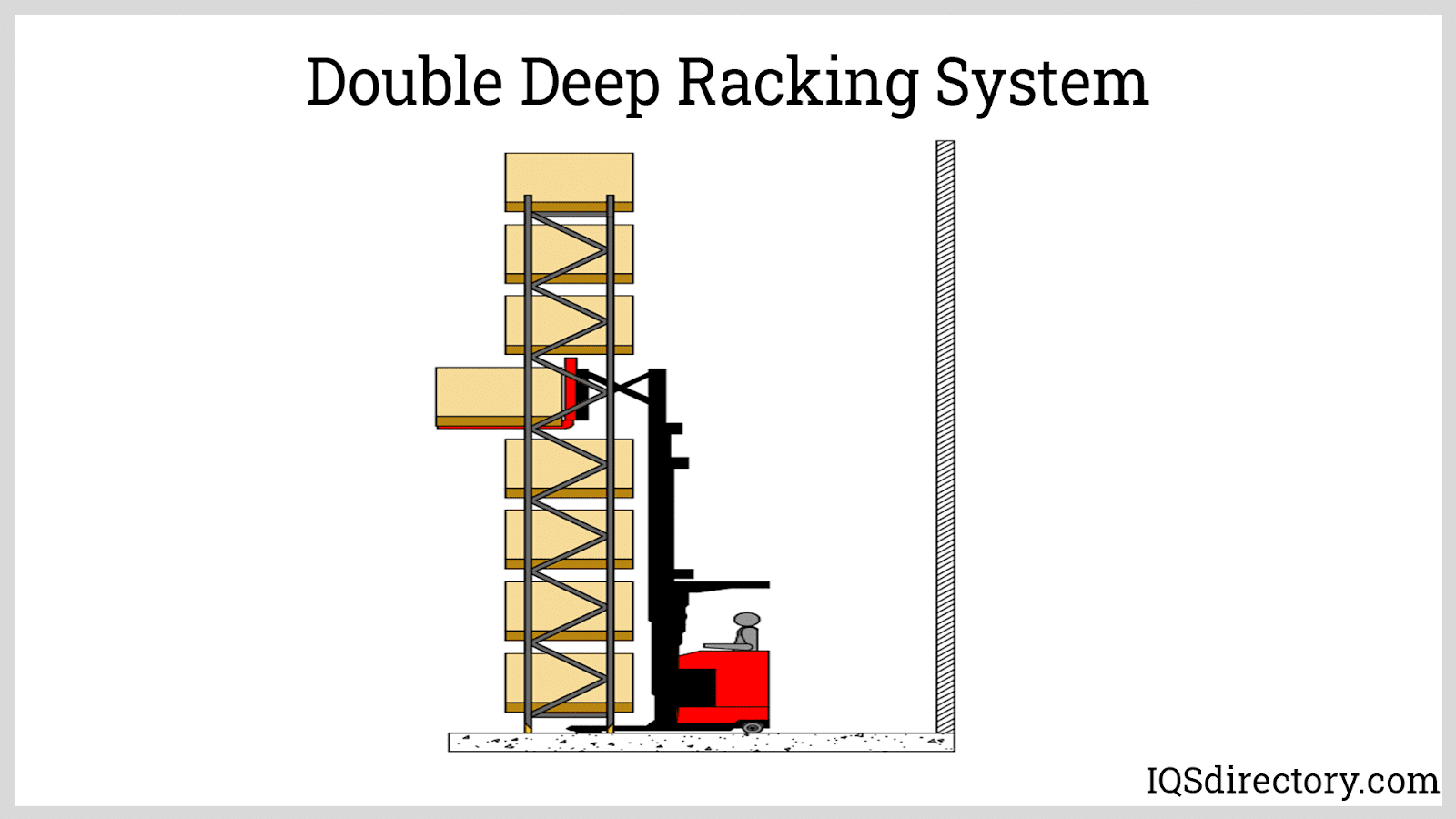

Roller racks consist of slightly inclined lanes fitted with rollers or wheels. When items such as cartons or pallets are loaded at the higher (rear) end, gravity causes them to move forward toward the picking face as preceding items are removed. This self-replenishing mechanism ensures continuous product availability at the picking position, streamlining order fulfillment and restocking processes.

To control movement and prevent damage, many roller rack systems incorporate speed controllers or brakes, especially when handling heavy or fragile goods. These components slow down the descent of inventory, ensuring smooth, controlled movement and safe access for workers.

Key Components of Roller Rack Systems

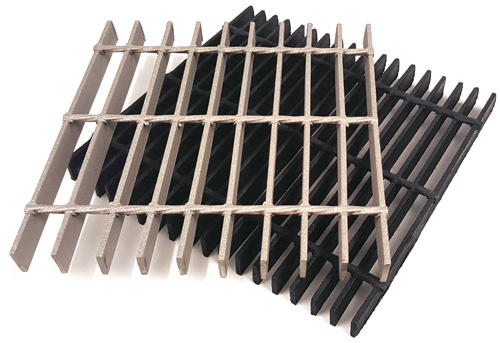

- Rollers/Wheels: Made from durable materials such as galvanized steel or polymer, rollers facilitate smooth movement of loads.

- Frame and Supports: Sturdy frames provide structural integrity for high-density storage and can be customized for different load capacities.

- Guides and Lane Dividers: These elements help keep inventory aligned and prevent cross-lane migration, crucial for SKU separation.

- Brakes and Speed Controllers: Essential for safe operation, especially on longer or steeper lanes.

Roller Rack Installation: What to Know

Proper installation is critical for the safety, longevity, and performance of your roller rack system. Roller racks can typically be installed up to a height of 11 meters, supporting both light and heavy-duty applications. Installation involves careful planning of beam elevations, alignment of bays, and secure fastening of wedge locks and connectors to ensure the entire structure is perfectly plumb in both cross-aisle and down-aisle directions.

If you’re considering a roller rack installation, keep in mind:

- Load Analysis: Assess your inventory weights, load profiles, and desired storage density to select the appropriate rack configuration.

- Floor Conditions: Ensure floors are level and can support concentrated loads imposed by high-density storage systems.

- Integration with Existing Systems: Roller racks can be installed as standalone solutions or retrofitted into existing pallet racking for enhanced flexibility.

- Compliance: Work with experienced installers and manufacturers to ensure your system meets local safety codes and fire regulations.

Types of Roller Racks: Comparing Storage Solutions

There are several types of roller racks, each engineered for specific storage needs and operational workflows. Understanding the differences can help you choose the best fit for your facility’s requirements.

Carton Flow Roller Racks

Carton flow roller racks are optimized for storing lightweight items such as cartons, boxes, and small totes. This system is commonly used in order picking operations, e-commerce fulfillment centers, and assembly lines where high SKU variety and fast access are critical. Carton flow racks help reduce travel time, streamline inventory rotation, and maintain product visibility at all times.

Pallet Flow Roller Racks

Pallet flow roller racks—also referred to as gravity flow racks—are designed for managing heavier loads stored on pallets. Pallet flow systems support deep-lane storage, where pallets are loaded from the higher rear end and travel via gravity rollers to the picking face at the lower end. This arrangement is ideal for environments with high inventory turnover, such as food distribution centers, beverage warehouses, and cold storage facilities.

Compared to conventional pallet racking, pallet flow roller racks can double or triple storage capacity, making them one of the most efficient high-density racking solutions available. They are particularly beneficial for storage of perishable consumer goods, freezer warehouses, and operations requiring strict FIFO rotation. Pallet flow racks can also be integrated with automated storage and retrieval systems (AS/RS) for even greater efficiency.

Roll-Formed Cantilever Racks with Rollers

The cantilever roller rack system is engineered for long, bulky, or awkwardly shaped items that cannot be easily stored on traditional pallet racks. With no upright aisles to obstruct access, cantilever racks are perfect for storing products such as furniture, carpet rolls, tires, pipes, textiles, and tubing. Adjustable lock-joint pin locks provide safety, strength, and ease of height adjustment, allowing for flexible storage of items with varying dimensions. Cantilever racks with rollers can be customized for manual or automated handling, depending on the application.

Heavy Duty Roller Racks and Custom Configurations

For industrial applications requiring storage of extremely heavy goods or large volumes, heavy duty roller racks are available. These systems feature reinforced frames, oversized rollers, and advanced safety features to support loads that exceed standard warehouse requirements. Custom roller rack solutions can be tailored to specific industry needs, including integration with conveyor systems, pick modules, and warehouse management software for real-time inventory tracking and optimization.

Roller Rack Applications: Where Are They Used?

Wondering if roller racks are right for your business? Explore these common use cases and industry applications:

- Distribution Centers & Warehouses: Maximize space utilization and accelerate order fulfillment for fast-moving SKUs.

- Cold Storage & Freezer Warehouses: Maintain FIFO rotation and temperature-sensitive inventory control for perishable goods.

- Food and Beverage Industry: Ensure efficient storage and rapid access to products with strict expiration dates.

- Manufacturing Plants: Streamline component supply for assembly lines and work-in-process inventory.

- Automotive & Aerospace: Facilitate storage of heavy or irregular parts, including tires, engines, and structural components.

- Retail and E-commerce Fulfillment: Support high SKU diversity and efficient picking for online orders.

- Pharmaceutical & Healthcare: Comply with inventory rotation requirements for medical supplies and drugs.

- Mezzanine Structures: Enhance upper-level storage without increasing fork truck traffic or compromising safety.

- Retrofitting Existing Racks: Upgrade traditional pallet racking to roller racks for improved flow without full system replacement.

Top Benefits of Roller Racks: Why Upgrade?

Roller racks deliver a wide range of benefits that directly impact warehouse efficiency, operational costs, and employee productivity. Here are the top advantages of adopting roller rack systems in your facility:

- Space Optimization: Achieve extremely high-density storage, freeing up additional floor space for other operations or expansion.

- Automated Inventory Replenishment: Gravity-fed lanes ensure the picking face is always stocked, reducing downtime and manual restocking efforts.

- Labor Efficiency: Less walking, lifting, and equipment use mean faster picking times and improved ergonomics for workers.

- Reduced Inventory Shrinkage: Improved product rotation and easier access help minimize losses due to obsolescence or spoilage.

- Flexibility and Scalability: Easily modify or expand your roller rack system as your business grows or inventory needs change.

- Enhanced Safety: Fewer forklifts in picking aisles lower the risk of incidents, while sturdy construction ensures load security.

- Cost Savings: By increasing storage density and productivity, roller racks contribute to lower operational costs and improved ROI.

Frequently Asked Questions About Roller Racks

What is the difference between gravity flow racks and traditional pallet racking?

Gravity flow racks (roller racks) use inclined rollers and gravity to move items automatically from the loading side to the picking face, ensuring continuous product availability and FIFO inventory management. Traditional pallet racking typically requires forklifts to move inventory and may not support FIFO rotation as efficiently.

How do I choose the right roller rack system for my warehouse?

Start by analyzing your inventory types (cartons, pallets, odd shapes), weight, turnover rate, and available floor and vertical space. Consult with experienced roller rack manufacturers to design a system that meets your specific operational goals and safety requirements. Consider scalability, integration with automation, and maintenance needs.

Can roller racks be customized for unique applications?

Yes! Many manufacturers offer custom roller rack solutions, including hybrid systems that combine pallet flow, carton flow, cantilever, and conveyor integration for specialized workflows.

Are roller racks suitable for cold storage or freezer environments?

Absolutely. Roller racks are frequently used in cold storage and freezer warehouses because of their ability to maximize capacity, maintain FIFO rotation, and withstand low temperatures with specialized materials and coatings.

Choosing the Right Roller Rack Manufacturer

Ready to purchase roller racks for your facility? Selecting a reputable manufacturer or supplier is critical to ensuring quality, safety, and long-term value. Here are some key criteria to guide your decision:

- Experience and Reputation: Look for manufacturers with proven track records in designing and installing roller rack systems for your industry.

- Customization Capabilities: Does the manufacturer offer tailored solutions for your unique storage needs?

- Quality Assurance: Evaluate material quality, engineering certifications, and warranty options.

- Customer Support: Consider after-sales service, maintenance, and technical support offerings.

- References and Case Studies: Ask for examples of successful projects similar to yours.

To help you make an informed decision, compare at least five roller rack manufacturers using our comprehensive roller rack directory. Each manufacturer’s business profile page highlights their areas of expertise, product capabilities, and contact information. Use our patented website previewer to review each company’s specialization, and our simple RFQ (Request for Quote) form to reach multiple suppliers with a single inquiry. Getting multiple quotes ensures you receive the best value and system for your operational requirements.

Roller Rack Maintenance and Safety Best Practices

Ensuring the ongoing performance and safety of your roller rack system requires regular maintenance and adherence to best practices:

- Routine Inspections: Check rollers, frames, and supports for wear, alignment, and secure fastening.

- Cleaning: Keep roller lanes free of debris and obstructions to maintain smooth operation.

- Load Limits: Adhere to manufacturer-specified load ratings to avoid overloading and potential damage.

- Training: Provide employee training on safe loading/unloading procedures and system use.

- Emergency Procedures: Establish clear protocols for addressing jams, blockages, or system malfunctions.

Get Expert Guidance on Roller Rack Systems

Still have questions about choosing, configuring, or installing a roller rack system? Our team of experts can help you navigate the selection process, compare solutions, and design a system tailored to your facility’s workflow and storage requirements. Contact us today to schedule a consultation or request a quote.

Ready to Transform Your Warehouse with Roller Racks?

Don’t let space constraints or inefficient inventory flow slow your business down. Roller racks and gravity flow racking systems are proven to boost warehouse productivity, increase storage density, and streamline order fulfillment. Whether you operate in food distribution, manufacturing, retail, or e-commerce, investing in a high-quality roller rack system can deliver measurable ROI and set your facility up for long-term success.

Start your search: Browse our roller rack manufacturer directory or request a quote today to compare features, pricing, and expert support options for your next storage project.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services