Cantilever racks are storage systems that are designed for the storage of long, oversized, or bulky materials. These materials include steel trusses, plasterboard, piping, and PVC carpet. A cantilever rack does not offer any vertical obstruction in the storage area. Cantilever racks consist of arms that attach to the uprights for providing the support structure to store items. For additional stability, sway braces may be put between the uprights. Read More…

Ridg-U-Rak produces more than 100 million pounds of pallet rack, high density storage rack and specialized rack systems annually. A customer-centric, full-service pallet rack producer with over 400,000 square feet of production and warehouse space, Ridg-U-Rak offers engineering, design, project management and installation services that meet your pallet rack needs on time and on budget.

Steel King offers the industry’s widest selection of rack types, including roll-form and structural pallet racks, drive-in racks, gravity flow and push back storage systems, multi-level pick modules, automation integration, cantilever racks, portable racks, and custom shipping racks. Plus a full-line of guard rail and rack protection products. Full engineering staff and more than 200 standard...

Donobrog is a leading material handling supplier. Since 1985, we have provided high-quality pallet racks and racking systems. We offer many other products, including mezzanine staircases, flow racks, guard railing and more. Expect excellent service on simple and difficult jobs.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

At East Coast Storage Equipment, we specialize in providing robust, reliable storage solutions through our extensive line of storage racks. With decades of experience, we supply, install, and service a wide variety of high-quality rack systems, tailored to meet the diverse storage needs of warehouses, distribution centers, and industrial facilities.

More Cantilever Rack Manufacturers

Cantilever Racks: The Ultimate Guide to Design, Types, Applications, and Selection

Cantilever racks are an essential storage solution for warehouses, distribution centers, and facilities that handle long, bulky, or irregularly shaped materials. These heavy-duty racking systems are engineered for optimal flexibility, strength, and accessibility, making them a top choice for industries such as lumber, steel, manufacturing, construction supply, and retail. If you're asking, "What are cantilever racks?" or "How do I choose the best cantilever rack system for my warehouse?"—you've come to the right place.

How Do Cantilever Racks Work?

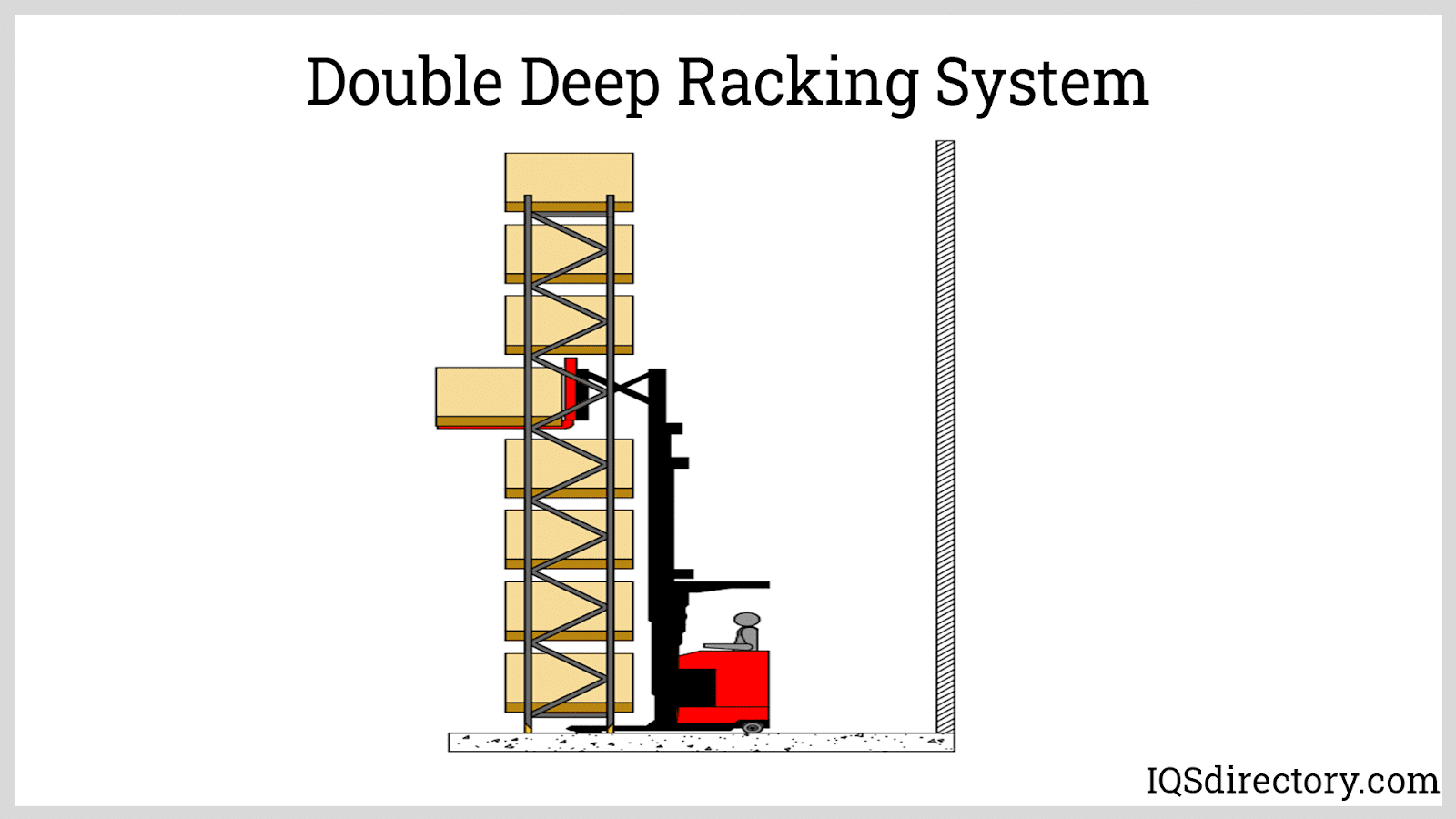

Cantilever rack systems are constructed with horizontal arms that extend from a central upright column, creating open storage levels free from vertical obstructions. This design allows for the efficient storage of lengthy and oversized items—such as steel pipes, PVC tubing, lumber, furniture, and sheet materials—that would be difficult to store on traditional pallet racking. Depending on the specific inventory items, the arms of a cantilever system may be perfectly horizontal or inclined. Inclined arms help keep round items, like bar stock and tubing, securely in place and minimize roll-off risk.

Cantilever racks can be configured as single-sided or double-sided units. Single-sided cantilever racks are typically placed against the wall, while double-sided cantilever racks are arranged back-to-back to form accessible aisles. The open-base frame design increases forklift accessibility and streamlines loading and unloading processes, while adjustable arms provide flexible storage for products of varying dimensions.

Load capacities of cantilever racking systems vary based on configuration, height, and arm length. A properly engineered cantilever rack can support anywhere from 8,800 lbs to 34,800 lbs or more per column, making them suitable for both light-duty and heavy-duty storage applications.

Components of a Cantilever Rack System

Understanding the core components of cantilever racks is critical when evaluating which system best meets your storage needs. The main parts include:

Bases

The base anchors the cantilever rack to the warehouse floor, providing foundational stability and support. Bases are directly connected to the upright columns, ensuring the rack remains secure when subjected to heavy loads, seismic activity, or frequent use. The size and strength of the base impact the overall load capacity and safety of the rack system.

Upright Columns

Upright columns are vertical supports that connect to the base and determine the height of the rack system. They feature pre-drilled holes or slots for attaching cantilever arms at adjustable intervals, enabling customized storage levels. Uprights are used in both single-sided and double-sided cantilever rack units and are available in various heights and gauges to accommodate different load requirements.

Arms

Cantilever arms extend horizontally from the upright columns and serve as the primary support for stored products. Arms come in various lengths, capacities, and styles (straight or inclined) to suit different types of materials. Adjustable arms provide flexibility to store items of different widths, while bolt-on and welded options offer varying levels of strength and ease of reconfiguration.

Braces

Horizontal and diagonal braces connect the upright columns together, providing critical lateral stability and rigidity to the rack structure. Proper bracing ensures the integrity of the system under heavy loads and helps prevent collapse or deformation.

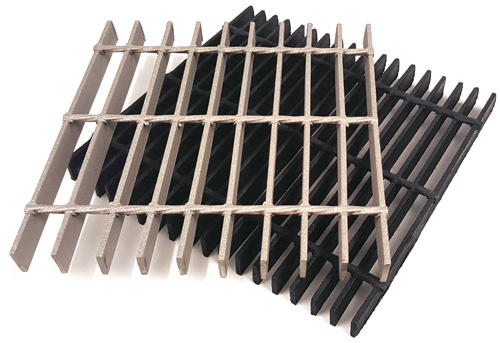

Decking

Decking options, such as wire mesh, steel panels, or wood, can be added to cantilever arms to create a solid shelf surface. This is especially useful for storing smaller, irregular, or non-uniform items that require a flat surface. Decking also increases the versatility of cantilever racks in applications involving awkward or odd-sized materials.

Types of Cantilever Racks

When selecting a cantilever racking system, it's essential to understand the two primary types: structural cantilever racks and roll-formed cantilever racks. Each offers distinct advantages based on your warehouse requirements, budget, and the nature of the products you need to store.

Structural Cantilever Racks

Structural cantilever racks are constructed from hot-rolled structural steel, often utilizing heavy-gauge "I" beams for maximum strength and durability. Components are typically bolted or welded together, resulting in a rack system with superior load-bearing capacity and resistance to impact or damage. Structural racks are the preferred choice for high-capacity, heavy-duty, or outdoor storage applications, where robustness and longevity are paramount.

Red steel cantilever racks—manufactured from structural-steel I-beams—are especially popular for their enhanced rigidity, versatility, and ease of access. These racks are available in both double-sided and single-sided configurations, allowing for maximum space utilization and warehouse layout flexibility.

Common uses for structural cantilever racks:

- Outdoor storage yards for lumber, pipe, steel, and building materials

- Warehouses requiring frequent forklift access and high load capacities

- Facilities with harsh or demanding environments

- Storing extra-long or extremely heavy items

Roll-Formed Cantilever Racks

Roll-formed cantilever racks are made from cold-rolled steel, resulting in a lighter-weight and more cost-effective racking option. Roll-formed components are typically slotted and bolted together, enabling easier assembly, disassembly, and reconfiguration as warehouse needs change. While roll-formed racks offer lower load capacities than their structural counterparts, they are still highly durable and suitable for many medium-duty and heavy-duty storage applications.

Medium-duty and heavy-duty roll-formed cantilever racks are ideal for warehouses that require flexible storage and quick installation. Their lighter construction makes them easier to relocate or adjust as inventory needs change.

Common uses for roll-formed cantilever racks:

- Indoor warehouse storage for piping, tubing, sheet metal, and lumber

- Facilities with moderate load requirements

- Retail environments or distribution centers with changing inventory

- Applications where cost and flexibility are primary considerations

Specialty Cantilever Rack Systems

For unique storage challenges, custom and specialty cantilever racks are available. These include galvanized racks for corrosive or outdoor environments, mobile cantilever racks for flexible floor layouts, and heavy-duty cantilever racks designed for extreme weights or oversized materials. When evaluating specialty systems, consider factors such as corrosion resistance, seismic compliance, and compatibility with automated material handling equipment.

Applications of Cantilever Racking

Cantilever racks are a versatile storage solution across a wide range of industries. Their open, unobstructed design makes them ideal for handling materials that are difficult to store using traditional pallet racking. Common applications include:

- Lumber and Building Materials: Store dimensional lumber, plywood, drywall, steel beams, rebar, and plumbing pipes efficiently and safely.

- Manufacturing and Fabrication: Organize steel bars, aluminum sheets, tube stock, extrusions, and other raw materials.

- Retail and Wholesale: Display and store carpet rolls, vinyl flooring, doors, and large furniture pieces for easy customer access.

- Automotive and Aerospace: Store oversized parts, sheet steel, and wire harnesses within reach of production lines.

- Distribution and Logistics: Maximize warehouse space by storing irregularly shaped or oversized product inventory.

Are you wondering if cantilever racks are right for your facility? Consider the types of materials you need to store, the available warehouse space, and your inventory turnover rates. Cantilever racks offer unmatched flexibility and efficiency for storing long or bulky items, reducing product damage and improving workflow.

Benefits of Cantilever Racks

There are many advantages to choosing cantilever racking systems for your warehouse or industrial facility. Here are some key benefits:

- Customizable Design: Cantilever racks can be manufactured to virtually any length, height, or configuration to fit your exact storage requirements.

- Efficient Storage of Long and Flat Materials: Ideal for materials that are too long or awkward for traditional pallet racks, such as steel pipes, lumber, or sheet goods.

- Open, Linear Storage: With no front columns, cantilever racks provide unobstructed access for forklifts and material handlers—improving productivity and safety.

- Adjustable Arms: Easily add or reposition arms to accommodate items of all shapes and sizes.

- Improved Warehouse Productivity: Streamlines the storage and retrieval process, minimizing handling time and risk of product damage.

- Seismic Compliance: Cantilever racks can be engineered to meet local seismic requirements, ensuring stability and safety in earthquake-prone regions.

- Heavy Load Capacity: Structural and heavy-duty cantilever racks can handle significant weights with ease.

- Easy Installation and Reconfiguration: Most systems are designed for rapid assembly and adjustment as warehouse needs evolve.

- Space Optimization: Maximize vertical and horizontal warehouse space, especially for products that cannot be palletized.

- Versatility: Suitable for both indoor and outdoor use, with weather-resistant finishes available for harsh environments.

Drawbacks of Cantilever Racks

Despite their many advantages, cantilever racks may not be the ideal storage solution for every facility or application. Consider these potential drawbacks:

- Potential for Wasted Floor Space: If not properly designed or combined with standard lift trucks, cantilever racks may leave underutilized aisle space between racks.

- Higher Cost Compared to Standard Pallet Racks: Cantilever racks can cost two to three times more than selective pallet racking, especially for heavy-duty or custom configurations.

- Less Efficient for Palletized Goods: These racks are optimized for long, irregular items and are not ideal for standard pallet storage.

- Aisle Requirements: Each rack row requires aisle space for forklift access, which can impact overall warehouse density if not carefully planned.

- Requires Specialized Design: Proper assessment and engineering are needed to ensure safe load distribution and compliance with local codes.

How to Choose the Best Cantilever Rack System for Your Facility

Selecting the right cantilever rack system involves careful consideration of your unique storage needs, warehouse layout, material handling equipment, and budget. Here are some critical factors to evaluate when comparing cantilever rack suppliers and solutions:

- Material Type and Weight: Assess the size, shape, and weight of the items you intend to store. Heavier, bulkier materials may require structural racks, while lighter loads can be accommodated with roll-formed systems.

- Rack Dimensions: Determine the optimal height, arm length, and base depth needed to maximize space and ensure safe storage.

- Warehouse Space and Layout: Measure available floor space, ceiling height, and aisle width to plan for efficient access and movement.

- Load Capacity: Confirm that the chosen rack system can safely support the maximum anticipated loads, including dynamic forces from forklifts.

- Environmental Conditions: Consider whether racks will be exposed to the outdoors, high humidity, corrosive materials, or seismic activity, and select appropriate finishes or designs.

- Future Expansion and Flexibility: Evaluate whether your storage requirements may change and if the rack system can be easily modified or expanded.

- Compliance and Safety: Ensure your system meets all relevant safety standards, regulations, and seismic codes.

- Budget and Total Cost of Ownership: Compare not only the upfront cost but also long-term durability, maintenance, and potential for reconfiguration.

Need personalized recommendations? Ask: "What type of cantilever rack best fits my inventory and workflow?" or "How do I calculate the correct arm length and spacing for my materials?" These questions can help guide your selection process.

Comparing Cantilever Rack Suppliers: What to Look For

To ensure a successful purchase and installation, it's important to compare at least four reputable cantilever rack suppliers. Using our cantilever rack directory, you can explore supplier profiles, review their areas of expertise, and access detailed information about their capabilities. Each supplier features a business profile page and a direct contact form—making it easy to request information or a quote.

As you evaluate cantilever rack companies, use our proprietary website previewer to gain insights into each company's specialties, and leverage our RFQ (Request for Quote) form to contact multiple suppliers simultaneously. This comparison process helps you identify which supplier offers the best combination of product quality, customer service, price, and delivery timelines.

Ready to get started? Consider these common search prompts:

- Who are the top cantilever rack manufacturers in my region?

- What is the lead time for custom cantilever rack systems?

- How do I ensure my cantilever racks meet OSHA and seismic standards?

- Which supplier offers the best warranty and after-sales support?

- Can I get a free on-site assessment for my warehouse?

Frequently Asked Questions About Cantilever Racking

What is the difference between single-sided and double-sided cantilever racks?

Single-sided racks are placed against a wall and offer storage on one side; double-sided racks can be accessed from both sides and are usually arranged in aisles for higher storage density.

Can cantilever racks be used outdoors?

Yes, structural and galvanized cantilever racks are suitable for outdoor storage. It's essential to choose racks with weather-resistant coatings and proper drainage to prevent corrosion and maintain structural integrity.

Are cantilever racks safe for seismic zones?

Cantilever racks can be engineered to meet seismic requirements, including additional bracing and anchoring systems, to ensure stability and safety in earthquake-prone regions.

How do I determine the right arm length and spacing?

Arm length and spacing depend on the size and weight of your stored materials. Consult with a cantilever rack engineer or supplier to calculate safe load distribution and optimal storage efficiency.

Get Expert Help Designing Your Cantilever Rack System

Whether you're upgrading an existing warehouse or planning a new facility, choosing the right cantilever racking system is vital for maximizing storage, improving safety, and supporting efficient material handling. Our team of material handling experts can provide tailored recommendations, site assessments, and design services to ensure you get the optimal rack system for your needs.

Have more questions? Reach out today to request a quote, schedule a consultation, or explore custom cantilever solutions for your warehouse, factory, or distribution center.

Contact us now or use our RFQ form to connect with leading cantilever rack suppliers near you!

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services