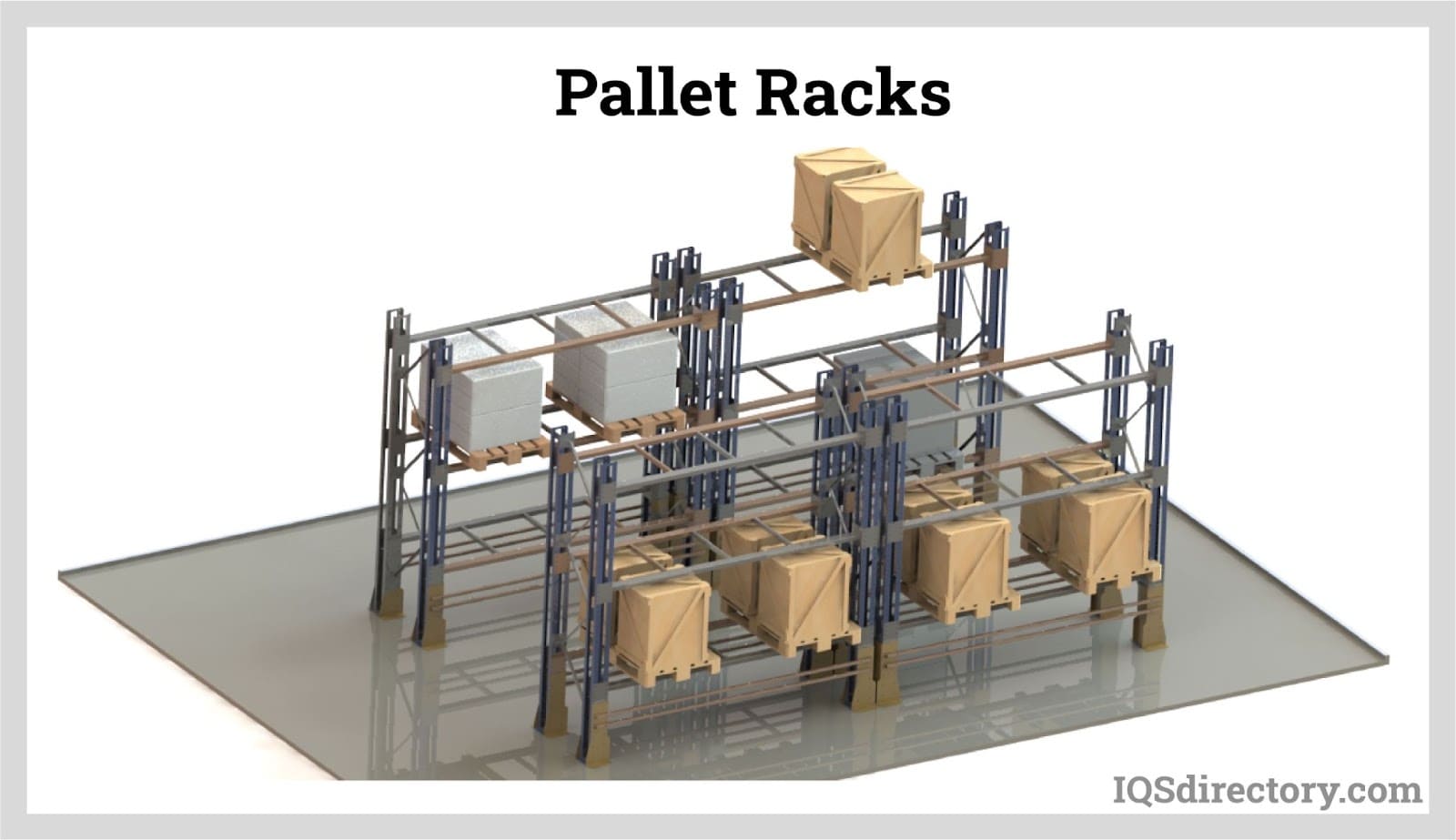

Flow racks allow materials to be introduced on one side of the unit and flow through it to the other side. They are also called live- storage racks; gravity-feed racks, point-of-use racks, and flow chutes. The number of levels, the number of lanes, and the external footprint define the characteristics of a flow rack. Read More…

Ridg-U-Rak produces more than 100 million pounds of pallet rack, high density storage rack and specialized rack systems annually. A customer-centric, full-service pallet rack producer with over 400,000 square feet of production and warehouse space, Ridg-U-Rak offers engineering, design, project management and installation services that meet your pallet rack needs on time and on budget.

Steel King offers the industry’s widest selection of rack types, including roll-form and structural pallet racks, drive-in racks, gravity flow and push back storage systems, multi-level pick modules, automation integration, cantilever racks, portable racks, and custom shipping racks. Plus a full-line of guard rail and rack protection products. Full engineering staff and more than 200 standard...

Donobrog is a leading material handling supplier. Since 1985, we have provided high-quality pallet racks and racking systems. We offer many other products, including mezzanine staircases, flow racks, guard railing and more. Expect excellent service on simple and difficult jobs.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

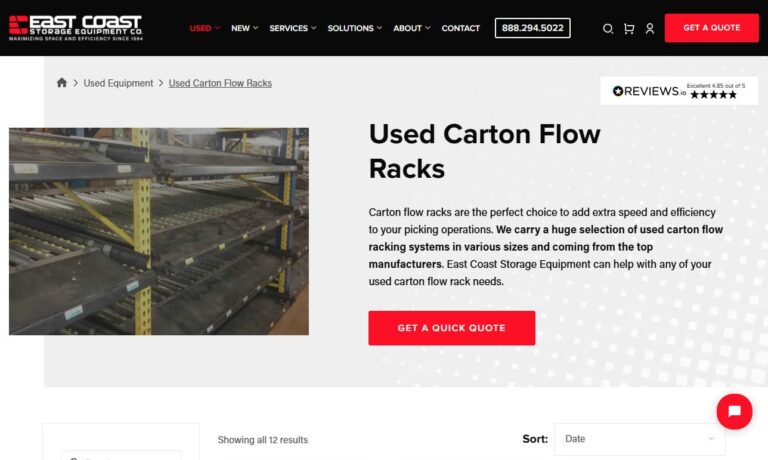

At East Coast Storage Equipment, we specialize in providing robust, reliable storage solutions through our extensive line of storage racks. With decades of experience, we supply, install, and service a wide variety of high-quality rack systems, tailored to meet the diverse storage needs of warehouses, distribution centers, and industrial facilities.

More Flow Rack Manufacturers

How Flow Racks Work

Flow racks utilize gravity in moving equipment, they don’t require human action. The flow mechanism can be roller tracks with wheels, flow rails, a surface at an angle, or a flat surface that allows free movement. Flow rack systems are designed in such a way that they have a slight slope downward starting from the load end and going down to the unload end. When a material is placed in the first position by the operator, the material starts to roll forward towards the unload end. In the lane, speed controllers are installed to ensure the safe travel of the pallet from the load end to the unload end. One of the uses of flow racks is to carry pallets from one end to the other.

Types of Flow Racks

The different types of flow racks include:

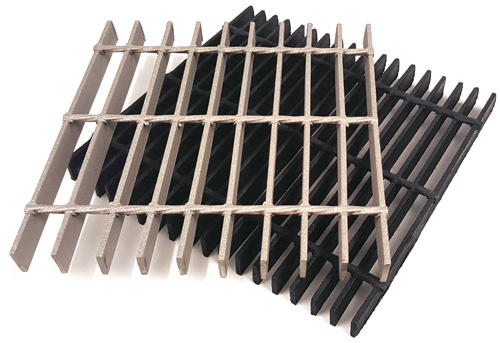

Flow Racks with Rollers

These types are the most commonly used of all types. Flow racks with rollers require two aisles: one for the insertion of pallets into the corresponding channel and the other for their extraction. Because of this separation, there is no interruption of the incoming and outgoing traffic and maneuverability by forklift operators is gained. These flow-racking systems usually include a safety aisle in the middle of the unit for emergency use.

Push-Back Flow Racks

In these types of racking systems, the loading of pallets is done from the same end in a way that makes only the front aisle necessary. This helps in saving a large amount of storage space. These racking systems are utilized with loads that are handled in line with last-in, first-out flows and have a medium turnover. The structure of push-back flow racks is made up of carts as well as rails. The incoming pallets are pushed into the channel by the handling equipment, while they are then drawn forward towards the front position of the channel by gravity itself. The structures that incorporate rollers can accumulate up to 6 pallets deep.

Flow Racks and Automated Systems

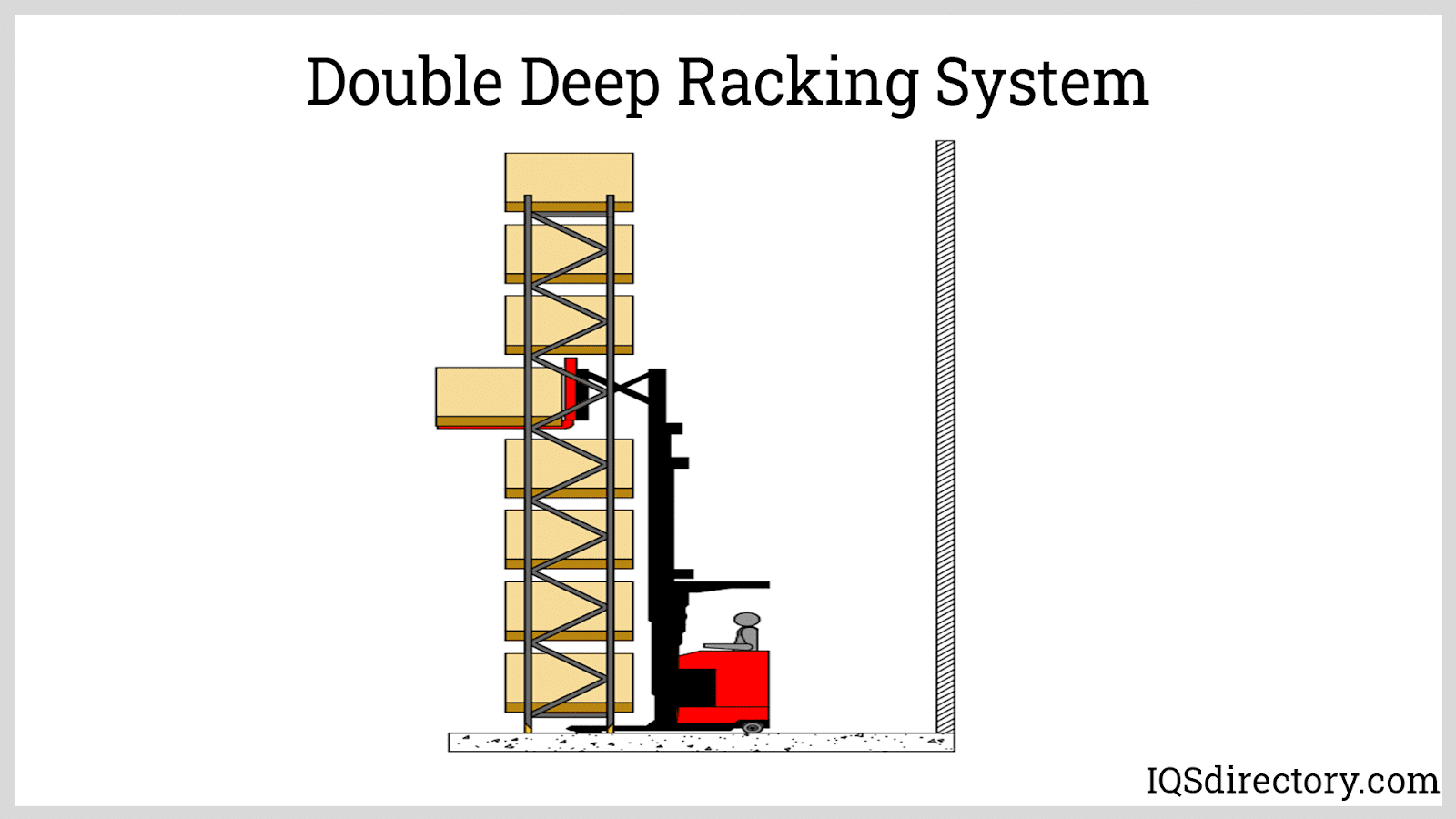

Flow-racking systems that consist of rollers can be installed with stacker cranes for pallets, thus they serve as the base storage system for a warehouse that is automated. This combination is not usual, but it goes a distance further from double-deep racking because there can be an addition of many pallets depth-wise.

Carton Flow Racks

They utilize gravity for speeding up the picking and order preparation process for equipment having a high turnover that follows first in, first out flow. These racking systems consist of rollers or wheels that serve to move the boxes to the unload end. Carton flow racks are designed for shortening picking travel times, freeing the picking area from any interference, and increasing storage space.

Application of Flow Racks

- Flow racks are designed to move cardboard boxes, unpackaged parts, bins, totes, pallets, or material of almost any kind.

- They separate the delivery area from the work zone of the operator. Between those two functions, flow racks create separation.

- They are mostly used in the manufacturing industries rather than in distribution.

- Flow racks are used for staging orders for shipment. They can also be used in picking systems for the storage of pallet loads of goods or case picking that is of high volume.

Benefits of Flow Racks

- They provide the right quantity of material to the operator in the right space at the right time. Flow racks reduce lifting, bending, guessing, and reaching in a process.

- Flow racks control the flow of material. A flow rack that is eight feet long is capable of holding eight feet worth of boxes. They offer support to production control as well as the logistics team for the application of the right process.

- Flow racks are cost-efficient and they provide storage space for dense material.

- Adjustment of shelves to meet product dimensions is possible.

Choosing the Proper Flow Rack Manufacturer

To make sure you have the most beneficial outcome when purchasing flow racks from a flow rack manufacturer, it is important to compare at least 5 companies using our list of flow rack manufacturers. Each flow rack manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each flow rack company website using our patented website previewer to get an idea of what each business specializes in, and then use our simple RFQ form to contact multiple flow rack companies with the same form.

55 Gallon Drums

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services