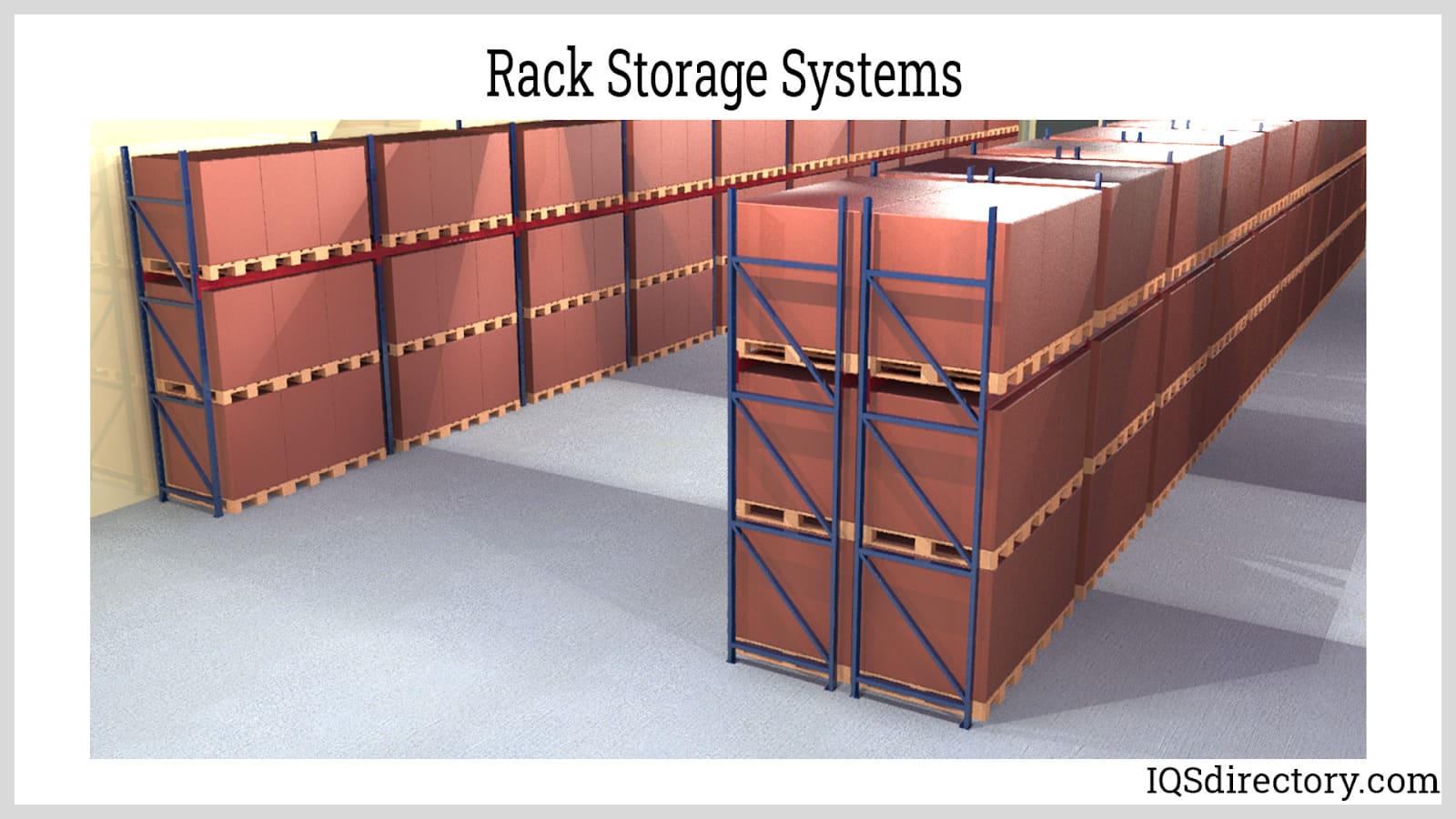

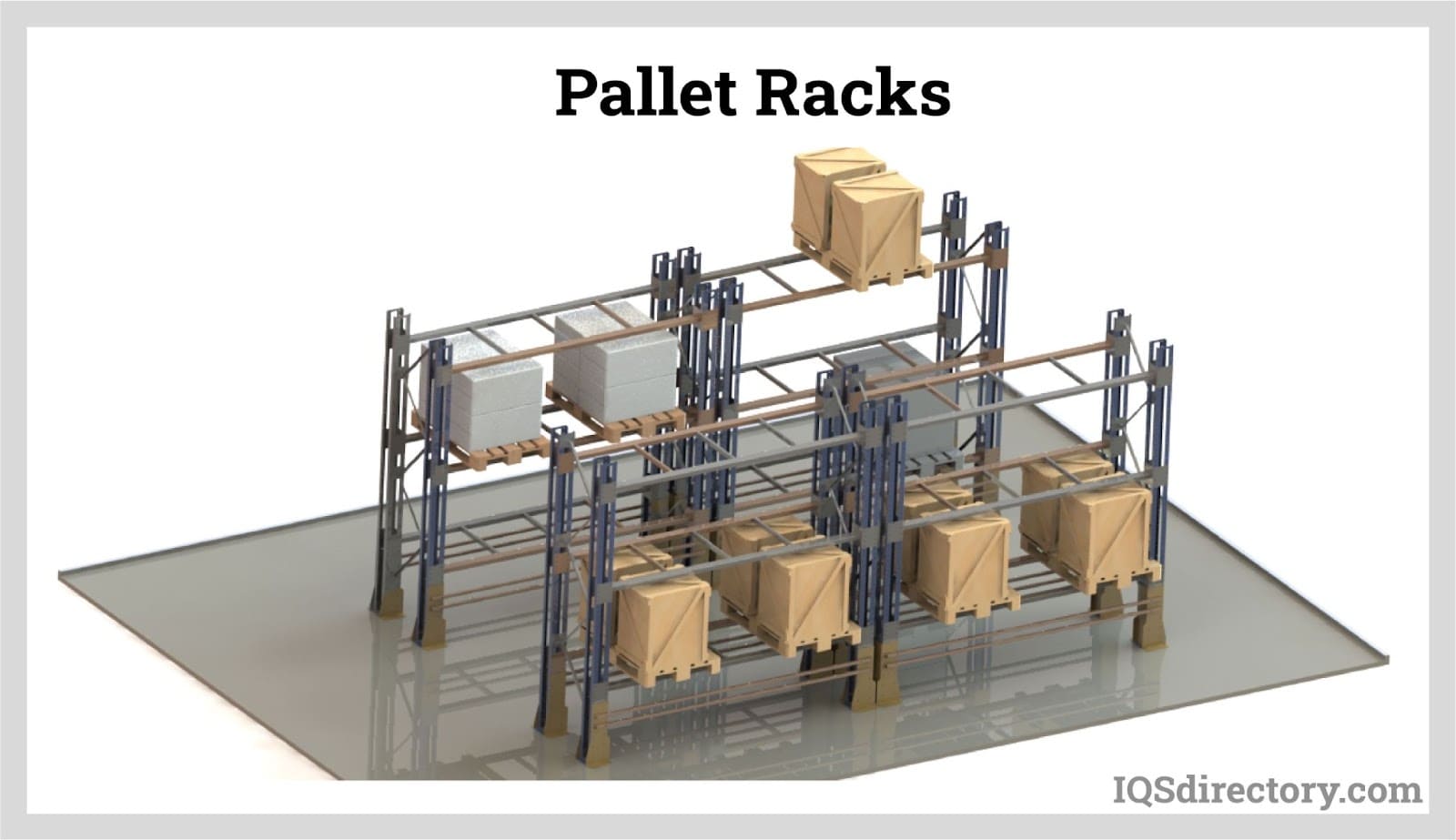

Industrial storage racks are steel structures that are suitable for storing large amounts of goods that are unitized on pallets or skids. They are an integral part of manufacturing plants, storage facilities, and warehouses. They are made and designed in a wide range of styles which are push-back racks, pallet racks, cantilever racks, and rolling racks. Read More…

Ridg-U-Rak produces more than 100 million pounds of pallet rack, high density storage rack and specialized rack systems annually. A customer-centric, full-service pallet rack producer with over 400,000 square feet of production and warehouse space, Ridg-U-Rak offers engineering, design, project management and installation services that meet your pallet rack needs on time and on budget.

Steel King offers the industry’s widest selection of rack types, including roll-form and structural pallet racks, drive-in racks, gravity flow and push back storage systems, multi-level pick modules, automation integration, cantilever racks, portable racks, and custom shipping racks. Plus a full-line of guard rail and rack protection products. Full engineering staff and more than 200 standard...

Donobrog is a leading material handling supplier. Since 1985, we have provided high-quality pallet racks and racking systems. We offer many other products, including mezzanine staircases, flow racks, guard railing and more. Expect excellent service on simple and difficult jobs.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

At East Coast Storage Equipment, we specialize in providing robust, reliable storage solutions through our extensive line of storage racks. With decades of experience, we supply, install, and service a wide variety of high-quality rack systems, tailored to meet the diverse storage needs of warehouses, distribution centers, and industrial facilities.

More Industrial Storage Rack Manufacturers

Products that have been palletized are mostly stacked to less than four layers before it is unsafe and prone to fall. Industrial racking systems allow manufacturers to store palletized products more than six stacks high, depending on the height of the warehouse or plant.

Considerations in Industrial Storage Racks

Before investing in industrial storage racks, it is crucial to note important factors to determine the viability of the project.

Available Storage Space

The initial step is to assess the amount of space that is available for storage rack construction. For an existing warehouse, all of the floor areas can be made use of. Industrial storage racks come in standard sizes.

Vertical Clearance

The amount of vertical space available needs to be assessed. The available vertical clearance has a direct influence on the storage racking density. The storage density can be minimized by the addition of one or two layers to an existing pallet with three layers. It is crucial to note also the clearance requirements for obstructions to airflow and fire suppression systems.

Unitized Load Dimensions

There is a need to consider the size and shape of the pallets that need to be stored. The industrial racking system must be designed to meet specific palletized loads.

Load

By the selection of the appropriate material, the frame must be capable of supporting the pallet load. Most of the industrial racking systems are manufactured using steel but their creation is through different methods. Heavy duty applications need steel that is made by the extrusion or hot rolling methods while lighter loads can make use of cold rolled steel.

The Volume of Incoming and Outgoing Goods

The volume of incoming and outgoing goods is linked to the target capacity of an industrial storage system. It is of utmost importance to know the rate at which goods are off-loaded or are being sold as well as the determination of seasons that have very low demands. Low storage space usually results in a lower rate of production and as a result, there will be a huge impact on the profit margins.

Types of Industrial Racking Systems

There are several types of industrial storage racks with different configurations and designs which are for specific applications.

Selective Racking

Selective racking can be viewed as large shelves that consist of storage space for only a single row of items. It has the lowest storage density. For the storage density to be improved, the racks can be arranged in a back-to-back pattern. Selective pallet racking can be combined with other system types of industrial racks. The selective racking system also offers several advantages like the operability of standard forklifts, design flexibility, simple construction that allows for easy reconfiguration, and the accessibility for cleaning and inventory accounting. Selective racking has frame and beam designs that are classified as slotted or teardrop racks

Teardrop Racks – Consist of the modified beam and frame attachments that can be expanded and configured much more easily without the use of machines.

Slotted Racks – Are also known as structural racks. They consist of a rectangular opening pair that is milled along with the frame that is vertical or upright.

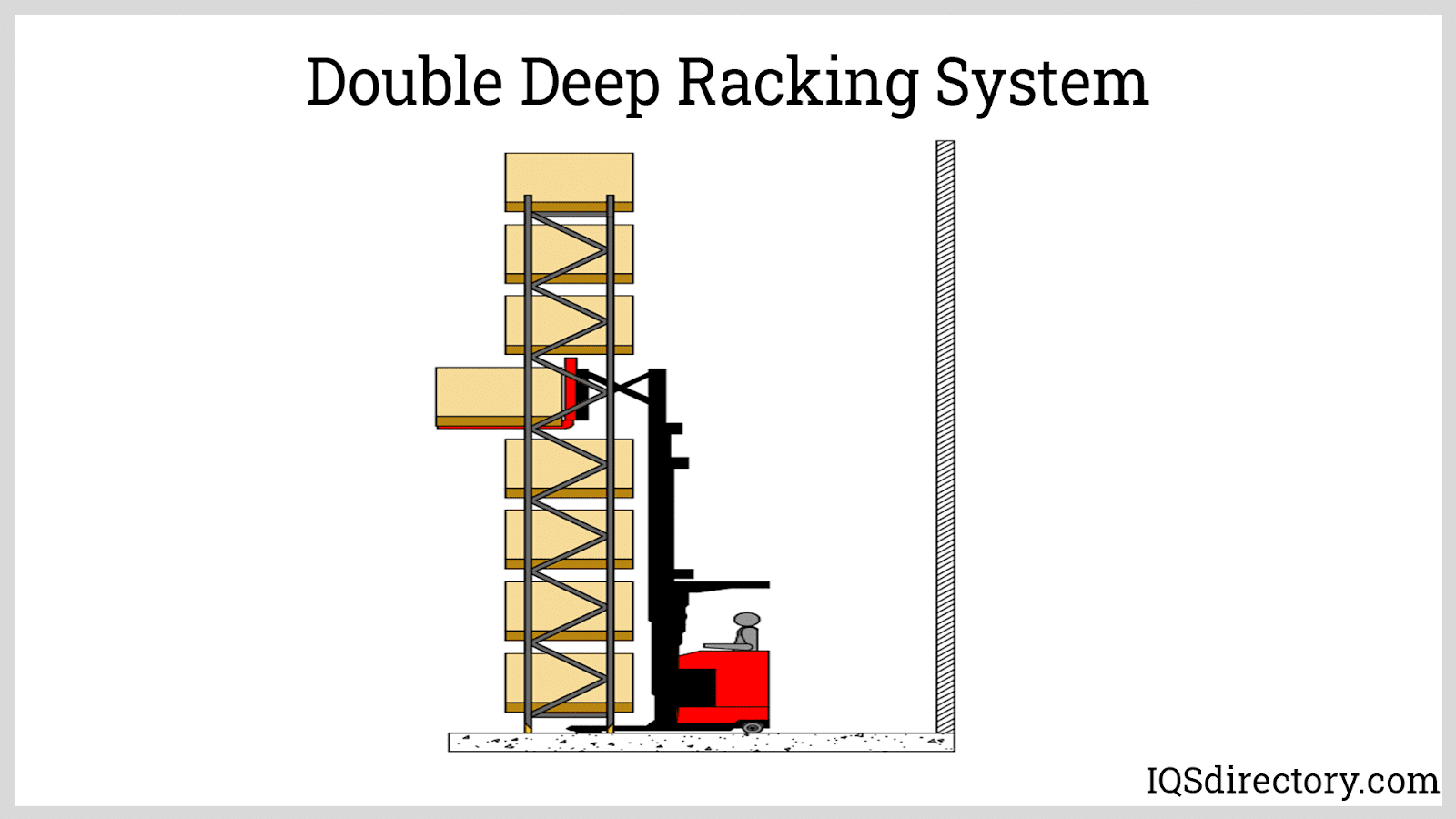

Double-Deep Pallet Racking

Double-deep pallet racking is a modification of selective racking. It uses two rows per pallet shelf instead of single pallet rows. Their design increases storage capacity by forty to sixty percent.

Very Narrow Aisle Racking

The concept of very narrow aisle racking is to continually improve space utilization of a standard selective. This is achieved by loading pallets by a forklift that is able to perform side loading. There are numerous types of industrial storage racking systems such as: push-back which involves the loading of the pallet on carts resting on rail pairs that are on each push-back lane. Drive-in and drive-through racking, gravity flow, cantilever, carton flow, mobile racking, high bay racking, and chrome wire racking are other examples.

Benefits of Industrial Storage Racks

Industrial storage racks offer several advantages that have made them essential in warehouses and storage engineering. Some of these are listed below:

- Efficient space utilization

- Easy inventory organization

- Fewer damaged goods

- Increased employee productivity

- Storage automation

- Increased safety

- Clean and contaminant-free handling

Choosing the Right Industrial Storage Rack Manufacturer

To make sure you have the most productive outcome when purchasing industrial storage racks from an industrial storage rack manufacturer, it is important to compare at least 5 to 6 companies using our industrial storage rack directory. Each industrial storage rack manufacturer has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the manufacturer for more information or request a quote. Review each industrial storage rack company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple industrial storage rack companies with the same quote.

55 Gallon Drums

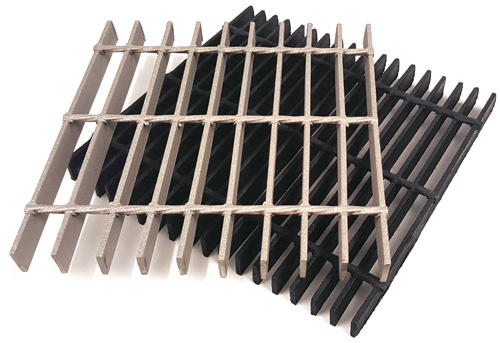

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services