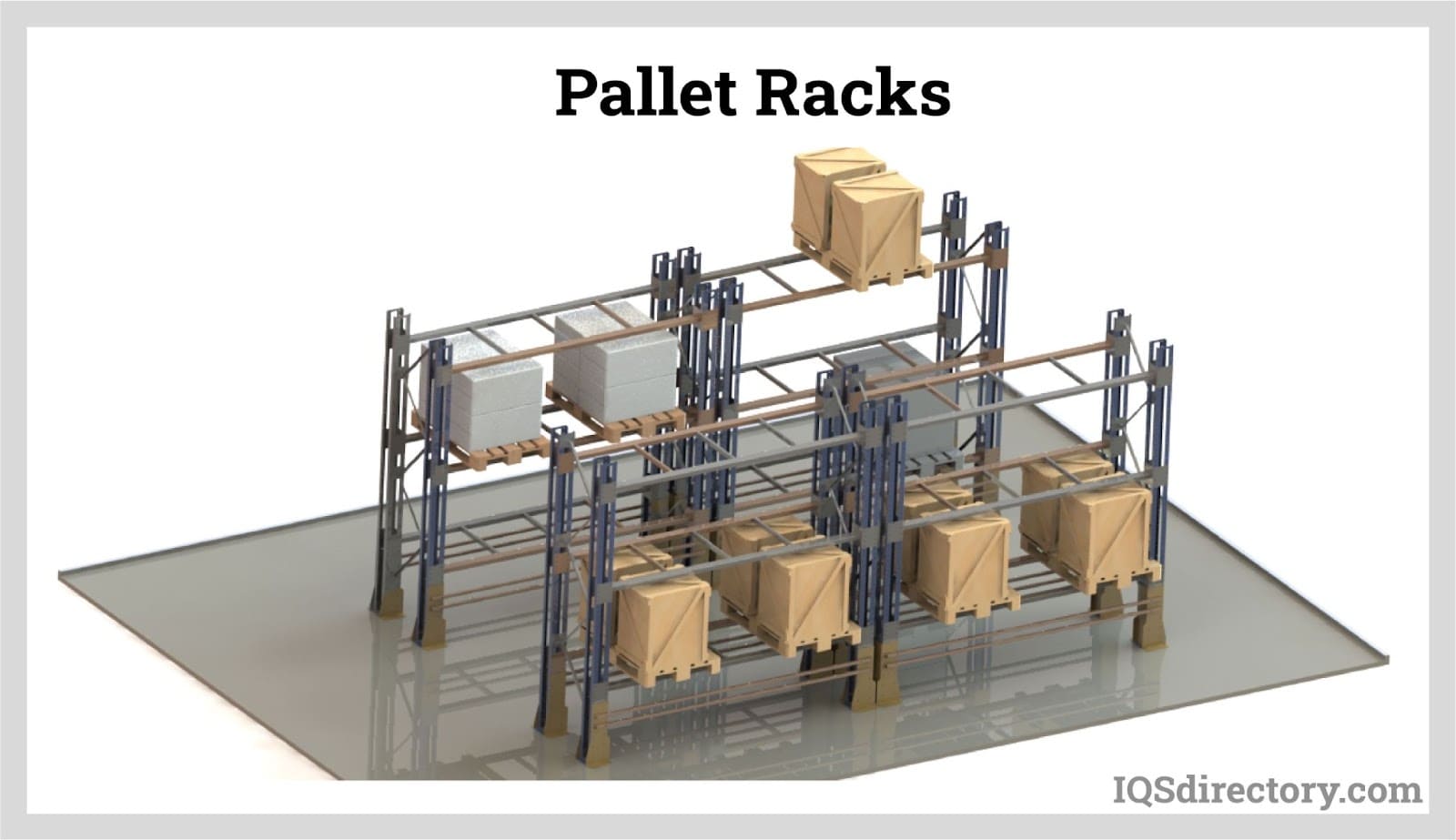

They range depending on what types of items are being stored, which could be boxes or pallets, and the method of stocking, which is either done by workers or lift trucks. Regardless, storage racks are used across every industry that shelves extra or unused materials, parts, tools, equipment and packaging. Read More…

Ridg-U-Rak produces more than 100 million pounds of pallet rack, high density storage rack and specialized rack systems annually. A customer-centric, full-service pallet rack producer with over 400,000 square feet of production and warehouse space, Ridg-U-Rak offers engineering, design, project management and installation services that meet your pallet rack needs on time and on budget.

Steel King offers the industry’s widest selection of rack types, including roll-form and structural pallet racks, drive-in racks, gravity flow and push back storage systems, multi-level pick modules, automation integration, cantilever racks, portable racks, and custom shipping racks. Plus a full-line of guard rail and rack protection products. Full engineering staff and more than 200 standard...

Donobrog is a leading material handling supplier. Since 1985, we have provided high-quality pallet racks and racking systems. We offer many other products, including mezzanine staircases, flow racks, guard railing and more. Expect excellent service on simple and difficult jobs.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

At East Coast Storage Equipment, we specialize in providing robust, reliable storage solutions through our extensive line of storage racks. With decades of experience, we supply, install, and service a wide variety of high-quality rack systems, tailored to meet the diverse storage needs of warehouses, distribution centers, and industrial facilities.

More Storage Rack System Manufacturers

Industries using storage rack systems include the food and beverage processing, restaurant, electronics, pharmaceutical, farming, plastics and metal fabrication, medical and construction industries, among many others. Most systems are made out of metals like steel, aluminum or titanium because they are strong, durable and can withstand harsh industrial conditions. Some rack systems are mobile, and can be moved with the use of casters or are on a system of tracks, allowing each shelf to move in a linear direction.

Efficiency, effective use of space and organization are the three main factors when designing a storage rack system. Workers must be able to quickly and safely load and access the items when needed. The racks must be large enough and the appropriate configuration to hold the certain type of items, and strong enough to support their weight continuously for long periods of time.

There are two different methods to stocking and picking items in storage, which are commonly pallets or large boxes. The first is FIFO (first in, first out). This technique separates the stocking, which is done in the rear, and picking, which is done in the front. The storage racks usually have depth and are able to hold a large amount of pallets or boxes at once.

These shelves are often a series of rails or rollers that are situated on an incline. This way, when the front load is removed by a forklift, the rest of the items automatically move forward and waste no space. FIFO is often used with perishable food items that could spoil or expire, and keep inventory from getting lost or buried inside the shelves.

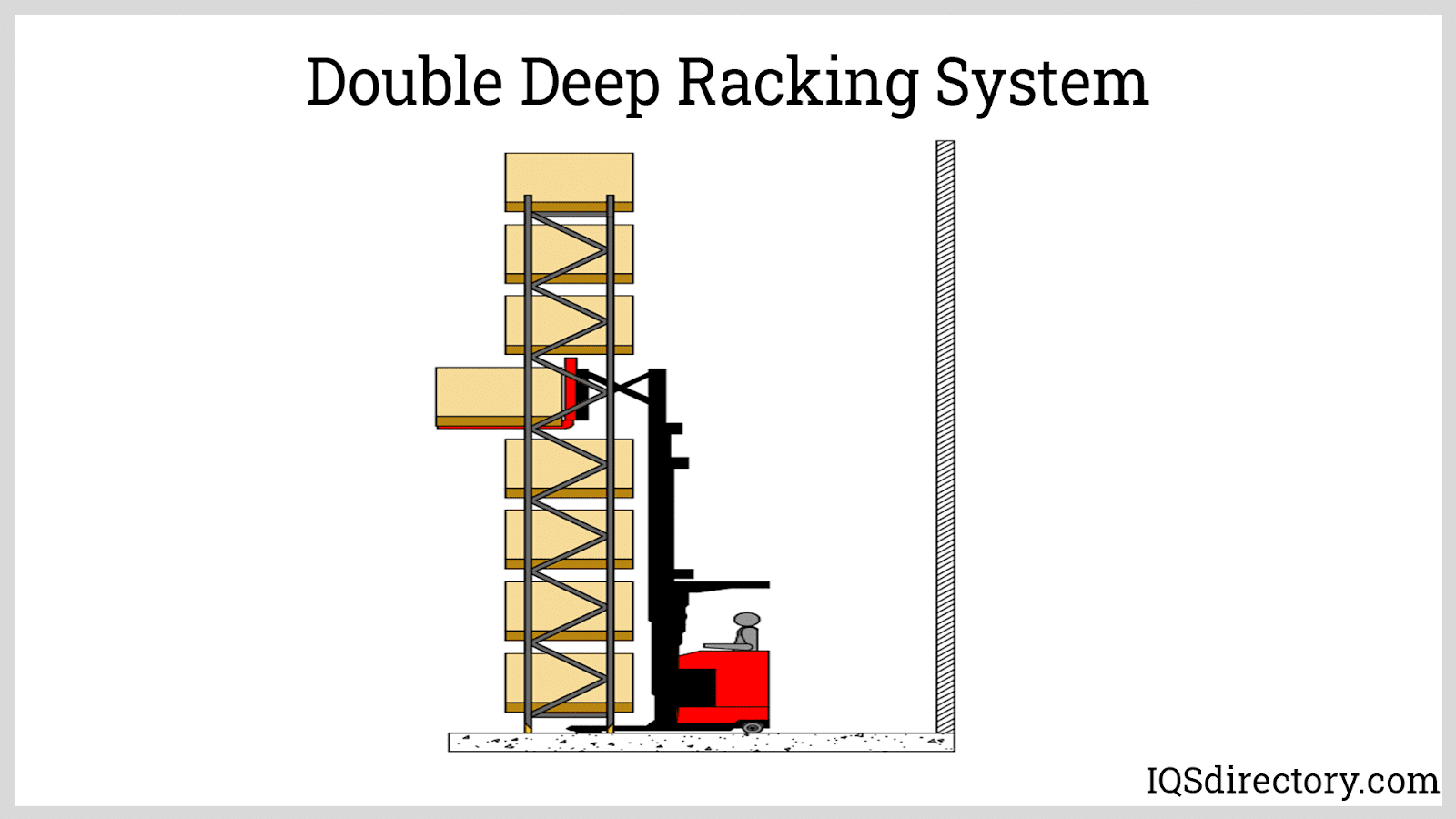

The other method of storing inventory is LIFO (last in, first out) and is mostly used for push back racks, which are also on a slant, but are positioned in rows of two, without an aisle between them. This eliminates the option to stock from the rear, leaving one aisle space to stock and pick from. Since products can sit for long periods of time in the back of the shelves with LIFO, it is used for only non perishable items. The main benefit is the space saved from less required aisle space and the ability to double up the shelving.

55 Gallon Drums

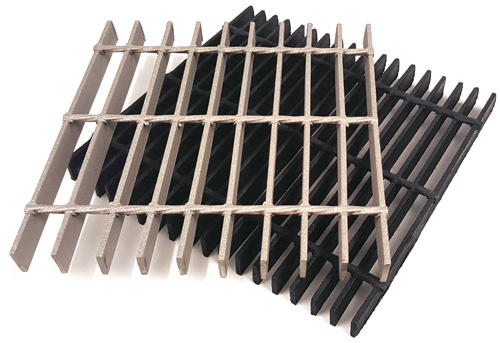

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

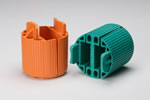

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services