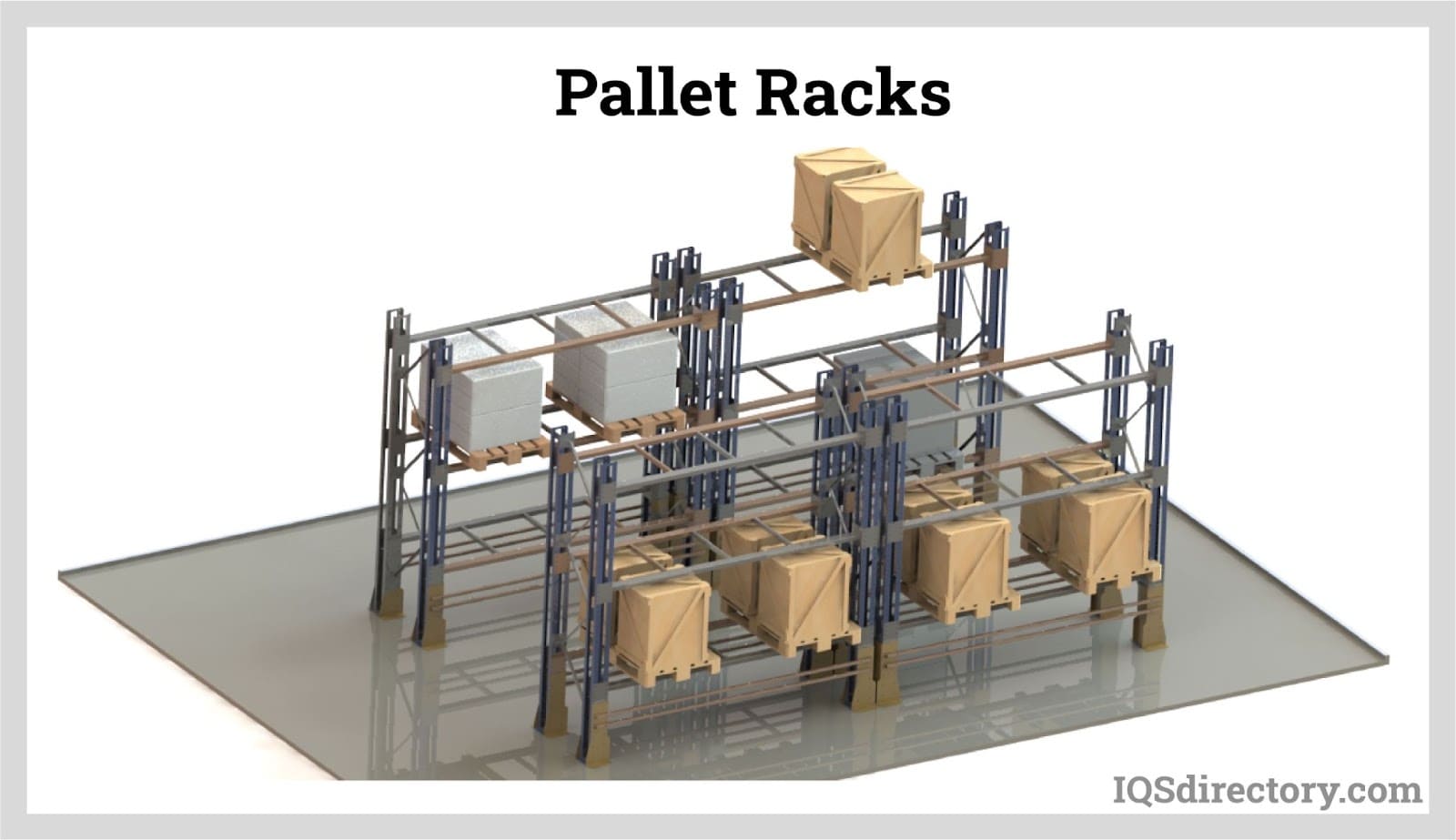

Warehouse racking (or pallet racking) is a material handling method for mass storage of items arranged on skids or pallets. Warehouse racking optimizes space usage and access to products piled up for inventory management. When storage space is limited, producers utilize racks to store large quantities of generally nonperishable goods. Read More…

Ridg-U-Rak produces more than 100 million pounds of pallet rack, high density storage rack and specialized rack systems annually. A customer-centric, full-service pallet rack producer with over 400,000 square feet of production and warehouse space, Ridg-U-Rak offers engineering, design, project management and installation services that meet your pallet rack needs on time and on budget.

Steel King offers the industry’s widest selection of rack types, including roll-form and structural pallet racks, drive-in racks, gravity flow and push back storage systems, multi-level pick modules, automation integration, cantilever racks, portable racks, and custom shipping racks. Plus a full-line of guard rail and rack protection products. Full engineering staff and more than 200 standard...

Donobrog is a leading material handling supplier. Since 1985, we have provided high-quality pallet racks and racking systems. We offer many other products, including mezzanine staircases, flow racks, guard railing and more. Expect excellent service on simple and difficult jobs.

Many types, sizes, makes & models of shelving available online at SJF.com. We buy & sell warehouse equipment with the nation's largest inventory of new and used material handling equipment: over 20 acres! Explore our website & find dealer direct savings on shelving & more types of material handling equipment.

At East Coast Storage Equipment, we specialize in providing robust, reliable storage solutions through our extensive line of storage racks. With decades of experience, we supply, install, and service a wide variety of high-quality rack systems, tailored to meet the diverse storage needs of warehouses, distribution centers, and industrial facilities.

More Warehouse Racking Manufacturers

Products that are palletized are typically only stacked up to three levels before it becomes risky and likely to collapse. Depending on the facility's height, a racking system enables producers to store five to seven stacks of high-palletized goods. In addition to managing finished goods, racking systems are also utilized to store raw materials and parts. Most goods can be accessed with selective racking, allowing for a wide range. Additionally, some distribution systems emphasize the first-in, first-out approach of inventory control, sometimes known as FIFO. Therefore, the oldest items in the warehouse inventory may be accessed thanks to a racking system, allowing them to be off-loaded first.

Types of Warehouse Racks

Push-Back Racking System

Push-back racking systems hold products that span 2 to 5 pallets and are typically used for bulk storage. A pallet is pushed to the front of the system when it is unloaded. Once loaded into the system, it pushes the following pallet back. Push-back racking systems frequently have slanted rails, sliding carts, and multiple lanes.

Cantilever Racking

Long products like lumber, pipes, tubes, and roofing materials are perfect for cantilever racking. It consists of upright columns with either one or both sides having cantilever arms. Manufacturers can change the vertical clearances between the arms depending on the product's bulk. Additionally, the angles can be changed to aid with load retention. Unlike conventional selective racking, cantilever racks do not have upright front frames that prevent loading. Along with long objects, it may also store items with odd shapes, such as furniture and appliances.

Selective racks

Selective racks are the most popular pallet system, offering access from an aisle. These warehouse-racking solutions are perfect for deep-reach, conventional, and small aisle racking. In addition, selective racks can hold one pallet deep and call for specialized narrow lift vehicles.

Flow Racks

Flow racks also called gravity racks, are frequently employed for high-density storage. Items are loaded at the higher end and removed at the lower end of this warehouse racking system utilizing a FIFO mechanism. As things are loaded and unloaded from the racks, the rotation of the merchandise becomes automatic. With flow racks, item movement is controlled by gravity rollers that move together with the rack load and include brakes or speed controllers. Fortunately, flow racks don’t require electricity because gravity powers them.

Drive-Through and Drive-In Racks

Drive-in and drive-through racks are best for high-density storage. The space provided by these steel-based warehouse racking systems allows the forklift to access each bay easily. It's crucial to remember that, in contrast to drive-through racks, drive-in racks have just one access point. Drive-in racks are suitable for the last in, first out (LIFO) strategy, often used for nonperishable or low-turnover products. Drive-in and drive-through racks may be built from floor to ceiling.

Advantages of warehouse racking

- Effective use of storage space: As was already said, racking optimizes vertical space that would otherwise go unused. High ceilings are crucial for warehouses designed to store racks to accommodate racks with longer bays.

- Easy inventory management: Racks are easier to manage than stockpiling. Selective racking, a form of racking system, enables the storage of various commodities while using the least amount of available space.

- Less damaged goods: To prevent damage to goods and products, racking systems must be implemented. Initially constructed of wood, racking systems have eventually evolved into remarkably stable metal structures that can stack items several feet in the air, with the height of the building serving as the only physical restriction.

- Racking systems improve employee productivity because racking systems make it simple to locate and access empty pallets. This minimizes tiny pointless motions that eventually add up to big losses.

- Storage Automation: The first stage in automating a warehouse is to adapt a racking system. This is accomplished by combining intelligent conveyor systems with guided cranes and forklifts. This can significantly reduce the cost of hiring new employees and streamline business operations overall, particularly for large distribution centers.

Choosing the Proper Warehouse Racking Company

To make sure you have the most productive outcome when selecting warehouse racking from a warehouse racking company, it is important to compare at least 5 companies using our warehouse racking directory. Each warehouse racking company has a business profile page that highlights their areas of experience and capabilities and a contact form to directly communicate with the company for more information or request a quote. Review each warehouse racking company website using our patented website previewer to get an idea of what each company specializes in, and then use our simple RFQ form to contact multiple warehouse racking companies with the same message.

55 Gallon Drums

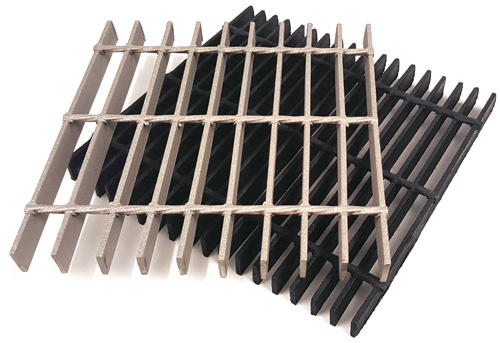

55 Gallon Drums Floor Gratings

Floor Gratings Mezzanines

Mezzanines Modular Buildings

Modular Buildings Plastic Containers

Plastic Containers Plastic Pallets

Plastic Pallets Plastic Tanks

Plastic Tanks Steel Shelving

Steel Shelving Stainless Steel Tanks

Stainless Steel Tanks Storage Racks

Storage Racks Work Benches

Work Benches Castings & Forgings

Castings & Forgings Bulk Material Handling

Bulk Material Handling Electrical & Electronic Components

Electrical & Electronic Components Flow Instrumentation

Flow Instrumentation Hardware

Hardware Material Handling Equipment

Material Handling Equipment Metal Cutting Services

Metal Cutting Services Metal Forming Services

Metal Forming Services Metal Suppliers

Metal Suppliers Motion Control Products

Motion Control Products Plant & Facility Equipment

Plant & Facility Equipment Plant & Facility Supplies

Plant & Facility Supplies Plastic Molding Processes

Plastic Molding Processes Pumps & Valves

Pumps & Valves Recycling Equipment

Recycling Equipment Rubber Products & Services

Rubber Products & Services